FourJaw For Continuous Improvement

FourJaw For Continuous Improvement

Factory Insight that drives Continuous Improvement.

Drive Improvement with Data.

Not Guesswork.

Uncover where time, energy, and capacity are being lost— and use the insight to know where processes can be improved.

Monitor the results of your improvement initiatives in real time and use trends to validate changes, share wins, and sustain progress.

With shared visibility into performance, teams are empowered to take ownership and collaborate on improvement efforts.

More Visibility. Less Complexity

Replace assumptions with facts.

With FourJaw, every improvement initiative is backed by evidence. Use live production data to test hypotheses, measure impact, and track KPIs over time. This ensures CI projects deliver measurable ROI and gain leadership buy-in.

Turn continuous improvement into a habit, not a one-off.

FourJaw’s intuitive dashboards and alerts empower teams at every level—from operators to managers—to spot inefficiencies, take ownership, and drive change. CI becomes embedded in daily routines, not just CI workshops.

Customer Testimonials

250 more windows produced each week from a 10% productivity increase.

“FourJaw has been a breath of fresh air for Listers…It has become the heartbeat of the business, enabling us to take a proactive and targeted approach to continuous improvement that benefits our people, customers and bottom line."

28% increase in OEE.

“From a continuous improvement point of view, we now have concrete evidence of where to focus our energy, helping with costings, budgeting and machine utilisation.”

19% increase in machine utilisation. Efficiency savings worth up to £30k per annum.

"FourJaw was an easy investment to make…. It has been adopted as part of the culture of our organisation, improving efficiency and communication and providing objective data to inform production schedules, operational improvements and machine investment strategies."

Data-Driven Decisions. Measurable Results

CI teams need accurate, accessible insight to identify root causes, measure impact, and drive long-term improvements.

FourJaw turns machine data into the clarity needed to prioritise the right changes, fast.

Customers of FourJaw can also opt in to join our Productivity Accelerator Programme, designed to help manufacturers unlock the full value of their machine data by linking it directly to continuous improvement projects.

Validate Improvement Initiatives

Measure the effect of your improvements in real-time using our productivity accelerator programme that uses a structured, repeatable process to accelerate productivity improvements and demonstrate measurable impact across your factory.

Compare before-and-after performance, track key metrics like OEE or uptime, and build trust across the business by backing every decision with data.

Get Everyone on the Same Page

FourJaw's machine monitoring system makes production data visible and actionable for everyone.

Whether it’s a daily huddle, kaizen event, or tier meeting, your teams can use real data to spot issues, prioritise actions, and take ownership of improvement.

Support Every Step of DMAIC

FourJaw provides a digital foundation for each step of the DMAIC process.

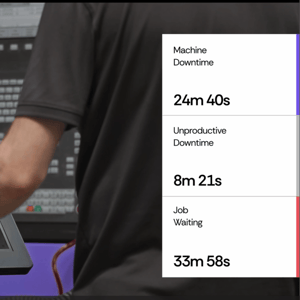

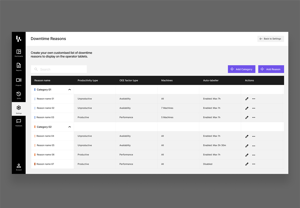

Define problems using real downtime data. Measure performance with live OEE and utilisation metrics, analyse root causes with downtime Pareto, improve by tracking interventions in real-time, and control results with ongoing visibility across machines and teams using dashboards to visualise the data.

Increasing Machine Utilisation With FourJaw

The results:

- More than 19% Machine Utilisation Increase

- €30,000 saved annually through efficiency and energy improvements

- Reduced time lost on each monitored machine by an average of 20 minutes per shift

- Driving a friendly, competitive culture across the factory floor

- Supporting a culture of Continuous Improvement

- Use FourJaw data to help inform its machine investment decisions

Trusted By Leading Manufacturers

Manufacturing Success Stories.

Leading manufacturer of windows & doors improves productivity by 10%

From 19% to 47% - How this factory Transformed Machine Productivity

Fernco transforms factory insight and productivity

Aerospace Manufacturer, AVPE Systems increases factory uptime by 30%

Ready to

Learn More?

See how FourJaw's production monitoring system can help you turn raw machine production data into real productivity gains to support your continuous improvement initiatives.

Frequently Asked Questions about Continuous Improvement with FourJaw

Continuous Improvement teams rely on accurate data to drive meaningful change. FourJaw helps CI teams to see where time and efficiency are lost, so they can focus their efforts where they’ll make the biggest impact.

Explore the answers to learn how our production monitoring platform supports Lean, Kaizen, and other CI programmes — from uncovering opportunities to measuring results and sustaining improvement.

FourJaw gives CI teams the data they need to identify, prioritise, and measure improvement opportunities. By automatically capturing machine utilisation and downtime reasons, FourJaw provides an accurate, real-time baseline of performance. This enables teams to target the biggest causes of lost productivity and track the impact of improvement projects with confidence.

FourJaw supports a wide range of CI methodologies — including Lean, Six Sigma, Kaizen, and TPM. It provides the live, factual data these frameworks rely on to uncover waste, validate improvements, and sustain gains.

Many customers use FourJaw alongside PDCA or DMAIC to guide improvement cycles from baseline through to control.

Operators use tablets on the shop floor to log downtime reasons quickly and accurately. This builds engagement by involving the people closest to the process and giving them a voice in identifying and solving problems.

Meanwhile, managers and CI leads use the web app to visualise patterns, share findings, and celebrate success across teams.

FourJaw customers commonly achieve 10–30% productivity improvements within just a few months. For example, AMS increased machine utilisation by 19% through data-driven CI, while Listers improved productivity by 10% and reduced energy waste. These results show how visibility and data empower teams to make focused, lasting improvements.