Testimonials

Testimonials

.png?width=300&name=Listers%20%20(1).png)

"FourJaw has been a breath of fresh air for Listers… It has become the heartbeat of the business, enabling us to take a proactive and targeted approach to continuous improvement that benefits our people, customers and bottom line."

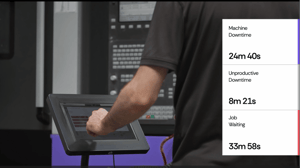

"FourJaw has provided us with real-time, fact-based insights into our operations. We can now pinpoint the true causes of downtime, track energy consumption, and make informed decisions about capacity and efficiency. This has helped us establish achievable utilisation targets and better manage our cost base.”

"FourJaw has delivered a significant and sustained improvement in the productivity levels we're getting from our manufacturing centres. Monitoring downtime, eliminating the various causes of waste in our processes, and deploying colleagues to where they are needed most has helped achieve a 30 per cent overall increase in uptime.”

Read case study

"We have a very personal and strong business relationship with FourJaw and they have helped us identify key areas for improvement and how to carry our business forward. The layout of the data is very well presented and allows us to establish a baseline and then plot growth targets over a timeline." See the full review on Capterra.

“The FourJaw team are incredibly proactive and enthusiastic, ensuring we were in full operation and maximising the value and opportunities from the new system. The FourJaw team regularly checked in and offered additional support sessions for training to keep us on track. A very good onboarding customer experience and one we would certainly recommend, thank you!”

"Excellent software for manufacturing companies to improve utilisation and productivity. Would highly recommend for anyone looking for easy to install and understand CNC machine monitoring".

"You may have been in the position where you think you need to buy another machine. Because you think you’ve got a capacity problem, but now we use FourJaw we can see where we have capacity that I'm not using."

"The product is very fast to deploy, and the team is great with supporting us to fit the product just for our individual use. Sure, it might not have all the features at this point that we might want to see, but what I love about it is that it's really a bargain if you look on the value compared to cost."

"FourJaw has been a revelation. We’ve already reduced energy consumption and identified further opportunities for improvement. We know precisely what machines are running and when, what they’re working on, how much energy they use, how long each job takes, and where time is being lost and why."

"If you’d asked me, before FourJaw, what the cycle times were, I genuinely would not have known. I now have a better feel for what’s involved, which has allowed us to change our production processes."

"We had a strong business before FourJaw but limited visibility of shop floor operations. We've addressed that with FourJaw, and the response from management and machine operators has been positive. Everyone has clarity of what needs achieving and has bought into our plans to improve productivity and profitability."

Manufacturing Productivity

Starts Here.

“FourJaw's machine monitoring solution has helped to quantify our initial thinking and put some value to it so that we could make more-informed data-based decisions. The recent product enhancements have made FourJaw a solution that is delivering real benefit from the top floor to the shop floor, it’s the team’s operational tool.”

.png?width=70&name=Happy%20(5).png)

"FourJaw was an easy investment to make and a giant leap forward in our digitisation journey. It has been adopted as part of the culture of our organisation, improving efficiency and communication and providing objective data to inform production schedules, operational improvements and machine investment strategies."

“It’s an absolutely fabulous tool to use and has become an essential aspect of our production planning processes. We are also using it for pricing. Sometimes, especially with a new job, we estimate production time based on similar components, but now we can see instantly how long the job actually takes.

The simplicity of using FourJaw's downtime monitoring software has convinced us to roll it out across the entire shop floor. It’s literally opening our eyes to see things for the first time.”

"I wish I had more time in my day to find faults with FourJaw, it really is simple and straightforward to use. My only problem is I'm too busy too implement the latest functions!"

“In the CNC cell, we have doubled the number of operatives because of the efficiencies we have been able to make. So we are employing more people in the cell, producing more products and the cost per unit of the product has decreased. That’s a big win.”

"FourJaw is the tool we use to maintain a ‘drumbeat’ of improvement and create a healthy, competitive environment to keep trying to do better"

"FourJaw facilitated conversations which were used to inform and educate operators, leading to a greater sharing of best practices, changed behaviours, and enhanced machine utilisation and productivity."

Manufacturing Success Stories.

Leading manufacturer of windows & doors improves productivity by 10%

From 19% to 47% - How this factory Transformed Machine Productivity

Fernco transforms factory insight and productivity

Aerospace Manufacturer, AVPE Systems increases factory uptime by 30%

Ready to

Learn More?

See how FourJaw's plug-and-play analytics can help you turn machine data into real productivity gains. What would you like to do next?