-1.png?width=300&name=Food%20manufacturing%20(4)-1.png)

Serve Smarter Production Insights

Real-time alerts and downtime tracking help teams react instantly, identify root causes, and prevent repeat issues.

Maximise Throughput on Bottling, Packaging & Filling Lines. Live performance tracking and historical insights help fine-tune line efficiency, reduce micro-stops, and hit throughput targets.

Keep Your Lines Cooking

F&B lines need frequent sanitation and product changeovers, which eat into production time.

With FourJaw, you can measure how long changeovers (actually) take, benchmark shift performance, and spot where time can be saved.

Empower Frontline Teams

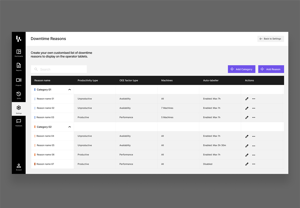

Operators often spot issues first but lack data to act or report effectively.

FourJaw empowers operators to log downtime reasons, surface issues, and support continuous improvement.

Factory Intelligence.

Starts Here.

What Makes FourJaw Essential for Food & Beverage Manufacturing?

FourJaw empowers Food & Drink manufacturers to achieve precision, efficiency, and data-driven insights.

FourJaw's Features

From productivity to sustainability, FourJaw helps Food & Beverage manufacturers stay ahead with real-time insights.

Gain capacity by improving processes and removing bottlenecks.

Simplify planning and communication for a more efficient factory floor.

Cut energy waste, streamline processes, and shrink your carbon footprint.

Ready to

Learn More?

See how FourJaw's plug-and-play analytics can help you turn machine data into real productivity gains. What would you like to do next?

Production line monitoring for Food and Beverage manufacturers FAQs

Monitoring mixers, fillers, conveyors, packaging, and bottling equipment in real time identifies stoppages and slowdowns, helping maintain continuous production.

Yes. Continuous tracking of production performance and downtime creates a traceable record that supports HACCP, BRC, and other regulatory standards.