Your Path to Maximum Manufacturing Productivity

Our team is here to support you, from the initial onboarding process right through to identifying improvement opportunities and working with you to measure the effectiveness of the process improvements in your manufacturing business.

Top Tips For A Successful Roll-Out

Meet The FourJaw Customer Success Team

FourJaw Productivity Improvement Customer Journey

Start

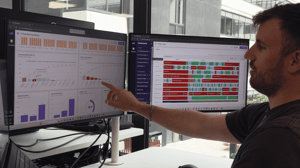

Our process for getting you configured and set up with FourJaw.![Manager looking at screens]()

1. Guided Tour

A guided tour of the platform that will be tailored to your manufacturing processes and challenges.

![FourJaw Rebrand 2025 Teaser (2)]()

2. Order Placed

Once the order is placed, we aim to dispatch your hardware within five working days.

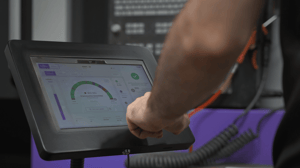

![FourJaw Machine operator using tablet (1)]()

3. Key Details

Provide details of the key people involved, the machines being monitored and the Wi-Fi details.

![FourJaw MachineLink Sensor Install]()

4. Installation

Plug-And-Play hardware installed by your own, qualified, electrician.

EMBED

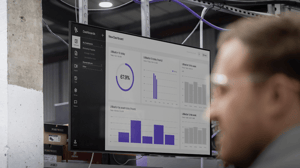

Our process to validate your data, train and drive cultural adoption.![FourJaw Production Dashboards showing machine utilisation-2]()

5. Data Classification

Confirm Data Classification is correct, per machine, calibrating FourJaw to your machines.

![FourJaw shop floor manager]()

6. Stakeholder Training

A virtual training session to get you and the key stakeholders confident with the platform.

![Kaizen Flow or Process Feature image for poster (4)]()

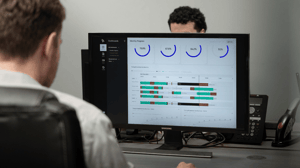

7. Data Analysis

Collect and analyse machine data to gain an understanding of the ‘current state’.

GROW

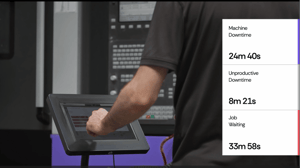

Our process to analyse, refine and optimise to drive continuous improvement and ROI.![FourJaw Overlay downtime-1]()

8. Optimise

Explore utilisation, OEE, and machine downtime reasons, and make changes to processes to drive improvement.

![FourJaw Operations Managers on shop floor]()

9. Measure & Refine

After 2-4 weeks measure and refine based on data insight following changes from step 08.

![FourJaw Production Dashboards showing machine utilisation on factory floor-1]()

10. Improvement & ROI

Look at the productivity improvements achieved, and calculate an ROI to support the business case for further roll-out.

Technology Trusted by Manufacturers of all Sizes

Taking your first step into the world of smart factory technology? We've put together a number of case studies showcasing how manufacturers who were once in your position have benefited from our machine monitoring platform.

Need Support?

Visit Our Knowledge Base

Find answers to common questions and keep up to date with the latest product release features at help.fourjaw.com

Contact The Team

You can contact our customer support team Monday-Friday, 8:00 am until 5:30 pm (GMT), simply complete the form or contact them via the details below.

- Address: Block 4, Level 2, Pennine Five, 18 Hawley Street, Sheffield, S1 4WP

- Phone: +44 (0) 114 400 0158

- Email: info@fourjaw.com

- Web: www.fourjaw.com

.png?width=300&name=FourJaw%20Rebrand%202025%20Teaser%20(2).png)

.png?width=300&name=FourJaw%20Machine%20operator%20using%20tablet%20(1).png)

.png?width=300&name=Kaizen%20Flow%20or%20Process%20Feature%20image%20for%20poster%20(4).png)