.png?width=300&name=Increase%20Production%20Capacity%20%20(2).png)

Deliver Precision. Minimise Delays

Real-time alerts and machine-level data allow teams to act quickly, fix issues fast, and keep lines moving and machines running.

Pinpoint inefficiencies, highlight bottlenecks, and enable fact-based decisions that support lean initiatives.

From stamping to assembly, processes must align tightly to avoid rework and waste.

FourJaw provides real-time insight into production stages, so teams can quickly spot slowdowns or mismatches.

In addition, you can keep track of production counts in real-time with automatic quality tracking and part counting.

Optimise Like an F1 Team

In manufacturing, operators are the drivers—skilled, focused, and fast. Your job? Be the pit crew. Ready to act, optimise performance, and keep production on track.

FourJaw gives you the real-time data to spot issues, fine-tune processes, and keep your team ahead of the competition.

Stay Informed. Stay on Track.

FourJaw removes the guesswork from production with live tracking and smart alerts, enabling you and your teams to stay informed and on track to deliver on time, every time.

Every Second Counts. Every Pound Matters.

FourJaw pinpoints underperforming machines and processes, helping you cut waste, boost efficiency, and protect your profit margins.

Manufacturing Productivity

Starts Here.

How it Works

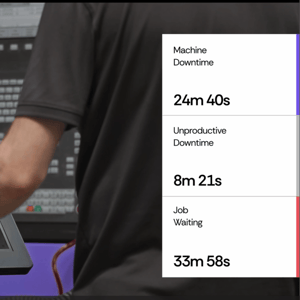

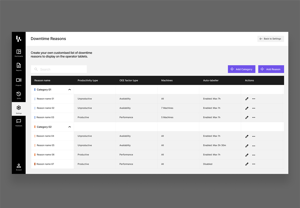

Tracking machine downtime is simple with FourJaw’s plug-and-play solution. Easily determine and tackle top downtime causes to keep production lines moving.

Clip the sensors to the machine's power cables.

Smarter Shifts. Start Here

Manual data capture is slow and unreliable.

FourJaw captures real-time machine data automatically, providing instant, accurate insights to spot inefficiencies and take action fast.

FourJaw's Features

From productivity to sustainability, FourJaw helps automotive manufacturers stay ahead with real-time insights.

Gain capacity by improving processes and removing bottlenecks.

Simplify planning and communication for a more efficient factory floor.

Cut energy waste, streamline processes, and shrink your carbon footprint.

Ready to

Learn More?

See how FourJaw's plug-and-play analytics can help you turn machine data into real productivity gains. What would you like to do next?

Production Monitoring FAQs for automotive manufacturing

Monitoring stamping, welding, assembly, and machining lines in real time highlights inefficiencies in cycle times, changeovers, and idle periods, helping to increase OEE without new equipment.

The cost of machine downtime for a vehicle

production line manufacturer can be

between $1.6 million and $2 million per hour,

with Tier 2 suppliers, reporting costs ranging

from £1,700 to £7,500 per hour.

But, machine monitoring solutions such as FourJaw provide real-time alerts and downtime tracking, enabling immediate response to stoppages, minimising delays across multi-stage production lines and minimising unplanned downtime.