Factory Insight. Made Simple

In highly regulated, precision-focused industries like medical devices and pharmaceuticals, efficiency, compliance, and quality are non-negotiable.

FourJaw helps manufacturers stay ahead by turning production data into actionable insight.

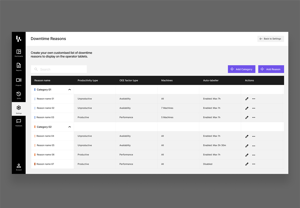

Equipment downtime delays production and increases the risk of contamination or spoilage.

FourJaw provides instant alerts and downtime tracking to keep critical production lines running smoothly.

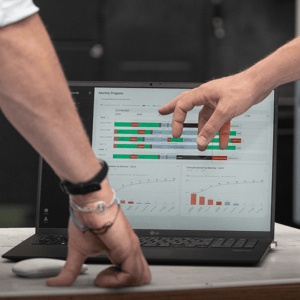

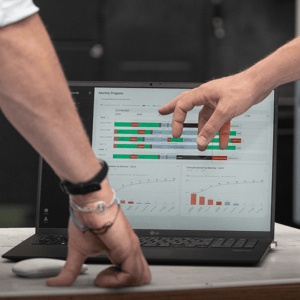

Leadership and planning teams need real-time data to manage capacity and ensure delivery.

FourJaw provides standardised, centralised performance insights across machines, teams, and locations.

CI efforts are often constrained by strict documentation and risk controls.

FourJaw delivers trustworthy, traceable insights that can be used to support safe, compliant process improvement initiatives.

FourJaw can track energy consumption at the machine, line or factory level, helping you identify waste, optimise efficiency, and reduce your carbon footprint.

Insights captured can be used by sustainability and quality teams to support ESG goals and make sustainability measurable and achievable—without disrupting operations.

Real-Time Insight for Predictable Production

FourJaw gives Medical device and Pharma manufacturers live visibility into machine performance, enabling them to stay on schedule and avoid costly delays.

Track utilisation, OEE, and downtime reasons to spot bottlenecks early. With job tracking and automated alerts, your teams stay aligned—and your deliveries stay on time.

Achieving a 20% Reduction in downtime

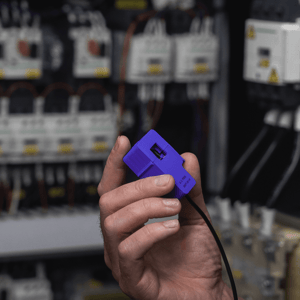

Install in Minutes

FourJaw works on ANY Machine, regardless of age or type.

Clip the sensors to your machine's power cables.

Connect the MachineLink IoT device to WiFi and mains power.

Use data insights to start identifying and removing inefficiencies.

A MedTech Success Story

Global healthcare manufacturer removes production backlog, reduces machine downtime by 20% and improves on-time delivery rate after installing FourJaw

FourJaw's Features

Everything you need to streamline and optimise processes to grow your business.

Gain capacity by improving processes and removing bottlenecks.

Simplify planning and communication for a more efficient factory floor.

Cut energy waste, streamline processes, and shrink your carbon footprint.

Ready to

Learn More?

See how FourJaw's plug-and-play analytics can help you turn machine data into real productivity gains. What would you like to do next?

Production Monitoring FAQS for medical and pharma manufacturing

Production monitoring tracks CNCs, moulding, assembly, and inspection equipment in real time, helping regulated manufacturers increase output without compromising compliance.

Read how Vernacare, a medical device manufacturer, did just that.

Yes. Tracking setup and changeover times allows teams to reduce variability, standardise processes, and maintain predictable output in regulated environments.