Aerospace

Aerospace

Get the factory visibility you need to make decisions with confidence.

Control & Clarity for your factory

Demand is high, but capacity is often limited by bottlenecks and inefficiencies.

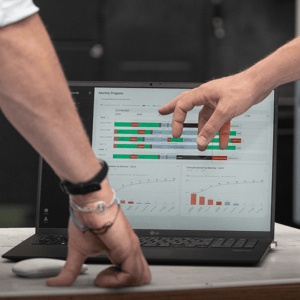

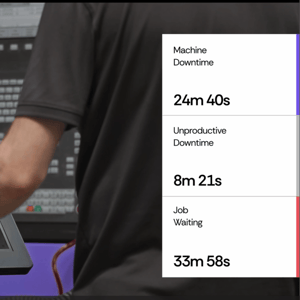

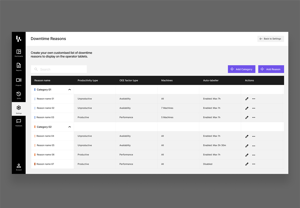

FourJaw exposes hidden downtime and inefficiencies so manufacturers can free up capacity without adding headcount or machines

Complex work orders with tight tolerances require close coordination and minimal disruption.

FourJaw tracks job-level performance, supports accurate scheduling, and enables better resource allocation.

In addition, you can keep track of production counts in real-time with automatic quality tracking and part counting.

Lean and CI programmes help reduce waste and improve competitiveness.

FourJaw provides the data insight and visibility teams need to prioritise actions and track impact over time.

Stay Ahead, Deliver on Time

FourJaw gives you the tools you need to keep you ahead of tight deadlines, maximise machine performance, and deliver actionable insights—so you can focus on what really matters:

Getting every component right, on time, every time.

Tackling Aerospace Backlogs with Data

This guide shows how data-driven insights and continuous improvement can help you overcome production delays without relying on more staff or new machines.

Optimise what you have. Stay agile. Deliver on time.

Aerospace Success Story

Aerospace manufacturers demand precision, and AVPE Systems achieved just that. By using FourJaw, they unlocked a 30% boost in factory uptime, slashing downtime and energy waste.

FourJaw's Features

Everything you need to streamline and optimise processes to grow your business.

Gain capacity by improving processes and removing bottlenecks.

Simplify planning and communication for a more efficient factory floor.

Cut energy waste, streamline processes, and shrink your carbon footprint.

Ready to

Learn More?

See for yourself how FourJaw's plug-and-play analytics can provide you with the factory intelligence you need to drive productivity, effortlessly.

Common FAQs about Production Monitoring for Aerospace Manufacturers

FourJaw’s production monitoring software provides real-time visibility of all types of machines used by aerospace manufacturers, including but not limited to: CNCs, grinders, composite layup stations, and assembly lines.

By identifying bottlenecks and hidden downtime, manufacturers can increase throughput without adding new machines or labour.