All Machines. One Platform

Get more from your machines. Not more machines.

Get accurate, real-time information from the factory floor to inform decisions across shifts, teams, and machines.

It’s not enough to know output is down - you need to know why. FourJaw provides the facts.

Spend less time chasing yesterday’s problems and more time improving where it matters.

Customer Testimonials

"FourJaw has delivered a significant and sustained improvement in the productivity levels we're getting from our manufacturing centres."

Monitoring downtime, eliminating the various causes of waste in our processes, and deploying colleagues to where they are needed most has helped achieve a 30 per cent overall increase in uptime.

“FourJaw is helping us move towards 4.0 based on our S&OP.”

It allows us every month to analyse with the directors to see our strengths and weaknesses and plan forward based on what we find. From a continuous improvement point of view, we now have concrete evidence of where to focus our energy, helping with costings, budgeting and machine utilisation.

“We’ve removed all back orders and are now in a position to deliver orders on time for customers worldwide.”

This is a tangible benefit of our unprecedented increase in machine productivity, and we’ve also improved staff retention with a calmer, less stressful working environment where operators have the autonomy to get on with the job.

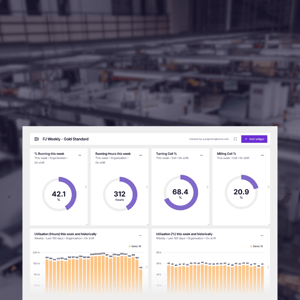

Factory Insight. Made Simple

Make faster, smarter decisions with data that works for you. Whether you're setting strategy, managing teams, or improving processes, FourJaw’s real-time insight puts you in control.

Production Dashboards give you instant access to the metrics that matter, so you can focus on driving performance.

Data you can use.

Decisions you can trust

Balance immediate problem-solving with strategic planning. FourJaw gives managers real-time visibility across their factory, without relying on manual reports.

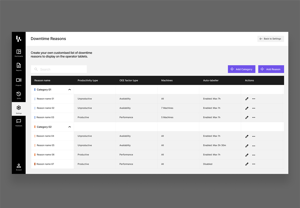

Our technology helps identify the root causes of inefficiency, allowing you to quickly resolve issues and maintain optimal performance.

Communicate Clearly. Operate Smoothly

High-performing factories run on clear communication.

FourJaw helps teams stay aligned by getting everyone on the same page. This allows managers to set clear expectations and enable fast, informed responses to what’s happening on the shop floor.

Stay Ahead of Disruption

Real-time event triggered alerts allow staff to escalate issues accordingly to remove production bottlenecks before they cause disruption, enabling you and your team to make sure jobs run on time and to budget.

Increasing Machine Utilisation With FourJaw

The results:

- More than 25% Machine Utilisation Increase

- Understanding the true time a job takes

- Being able to quote more accurately to improve profitability

- Driving a friendly, competitive culture across the factory floor

- Supporting a culture of Continuous Improvement

- Guided decisions for staff and equipment investments

Trusted By Leading Manufacturers

Manufacturing Success Stories

Leading manufacturer of windows & doors improves productivity by 10%

From 19% to 47% - How this factory Transformed Machine Productivity

Fernco transforms factory insight and productivity

Aerospace Manufacturer, AVPE Systems increases factory uptime by 30%

Ready to

Learn More?

Gain visibility of your factory operations. Book a personalised product demo and see how our production monitoring system can enable you to drive operational excellence.

Frequently Asked Questions for Manufacturing Leaders

FourJaw delivers real-time visibility of factory performance, giving leaders instant insight into machine utilisation, downtime, and production trends. This allows you to make informed decisions on capacity planning, investment, staffing, and improvement priorities — supported by data, not assumptions.

Check out our customer case studies that demonstrate the impact our technology has.

Manufacturers often see productivity gains of 10–30% within months of deployment, often without additional headcount or capital expenditure.

By uncovering hidden production downtime and inefficiencies, FourJaw enables teams to increase output, reduce energy costs, and maximise the value of existing assets — delivering a fast (but lasting) and measurable return on investment.

Yes. FourJaw provides accurate utilisation and downtime data that can be used for OEE tracking, shift or team comparisons, and management reporting.

Our production performance dashboards and automated email snapshots make it easy to share key metrics with stakeholders, helping align teams around performance goals.

FourJaw's plug-and-play hardware and secure cloud-based manufacturing software mean it is built for scale.

Whether you operate a single site or have multiple sites/plants worldwide, you can view and compare performance across sites in one platform.

A typical FourJaw installation (5-10 machines) and setup takes just a few hours, with insights available within days.

Once the hardware is installed, our customer success team works with key stakeholders to align the data insights with your goals, aiming to identify early opportunities and track measurable improvements from the off.

Our customer success team also provides customers with the opportunity to join our Productivity Accelerator Programme, ensuring your investment delivers both short-term wins and long-term cultural change.