Oil & Gas And Energy

Oil & Gas And Energy

Your Factory. Your Data. Your Competitive Edge.

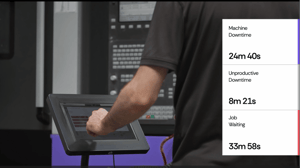

Unexpected machine stoppages can cause costly delays and disrupt critical project timelines.

FourJaw provides real-time alerts and downtime analytics so you can quickly identify issues and keep production running smoothly.

Precision and quality are non-negotiable when it comes to manufacturing for critical infrastructure.

FourJaw’s data insights help monitor machine performance and consistency, enabling early detection of anomalies to reduce defects and rework.

Balancing machine capacity and workforce across complex production schedules is challenging.

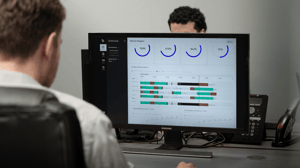

FourJaw delivers live visibility into utilisation and performance, empowering you to optimise workflows, increase throughput, and meet demanding deadlines.

13% Productivity Gain in One Day

Discover how, after just two days of installing FourJaw machine monitoring software, this Oil & Gas equipment manufacturer saw night-shift productivity go from 34 per cent on day one to 47 per cent on day two and constant from that day onward.

"FourJaw is giving us the ability to see areas of downtime that in the past we would have had to micromanage to discover".

Turn data into answers.

Whether you're producing wellhead equipment or drilling parts, precision and quality are non-negotiable.

Lost downtime, bottlenecks and a lack of capacity can often hold production back.

FourJaw enables you to know for a fact where inefficiencies are, giving you the confidence to make decisions that have an impact where it matters most.

Replace Opinions With Facts

Improve Efficiency. Gain Capacity

By monitoring and analysing production data, FourJaw will help you identify the best ways to save time and money for your factory.

We've helped precision machining customers achieve 25-30% time savings by giving them the tools to identify inefficiencies.

Real-time machine data provides you with the top reasons/causes of machine downtime.

Track machine and job status, ensuring you know the state of your machines at all times.

Instant notifications enable proactive action, preventing costly downtime.

Factory Visibility.

Made Simple

Frequently Asked Questions

FourJaw's machine monitoring solution is designed for use on all types of manufacturing equipment.

In oil and gas equipment manufacturing, our analytics software is frequently used with:

- CNC Lathe

- CNC Turning

- CNC Milling

- Drilling

- Oxy-Fuel Cutting Machines

- Laser Cutting

- Waterjet Cutting

- Plasma Cutting

- Grinding

- Inspection

- Packaging

- Weighing

Learn more about CNC machine monitoring with FourJaw.

Machine monitoring provides manufacturers with full factory floor visibility of how well machines are being utilised, by showing the machine downtime and uptimes.

With the FourJaw machine monitoring platform, operatives can categorise the reasons for the downtimes so factory floor managers get a clear picture of how productive the machines are. Here's a useful case study that shows how a manufacturer improved their machine utilisation by 400%.

Yes. Our machine monitoring platform was specifically designed to make machine monitoring accessible to manufacturers of all shapes and sizes, which of course meant we designed our platform to work with any type of machine, regardless of age, brand or model. So you can turn your 50-year-old machine into a 'smart machine', helping you to understand how productive your machines are.

FourJaw's machine monitoring software provides Energy usage data combined with Machine productivity data to help factories reduce their energy usage, energy costs and carbon footprint.

You can find out more about FourJaw's energy monitoring feature here.

No. Unlike traditional machine monitoring solutions, we designed our machine monitoring platform to be accessible, not only did we make it easy to install (minimising disruption to your shop floor) but we also made it affordable.

We offer monthly payment plans and you can install it yourself, so there are no high upfront installation costs often associated with traditional machine monitoring solutions. Find out more about the pricing plans we offer here.

Utilisation Data

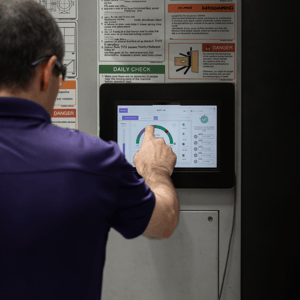

FourJaw starts with utilisation data in it's simplest form. The specially designed MachineLink hardware is a combination of miniature computer and current clamps. These two current clamps are typically attached to the total power incomer of the machine and the main drive unit, for example a spindle motor of a CNC machine.

This raw data is recorded every second and sent to our secure Azure cloud platform. The data is then instantly built into chunks of running and not running data, typically over 20-second periods, which is then displayed and categorised throughout the FourJaw platform.

What this provides is a very accurate measure of when the productive part of the machine experiences load and when it does not. Applied to this data is FourJaw's Machine Learning program which automatically classifies the data into productive/active and idle/inactive time. This means warm up runs and free air cycles are classed as idle time in the case of a CNC machine as the machines is not in its productive state.

Downtime reasons are inputted by the operator of the machine via a tablet which is installed beside the operator.

Each tablet is paired with a machine via the same FourJaw portal running on a Chrome browser.

When the MachineLink hardware, detailed above, measures a set period of idle time a pop-up appears on the platform asking the user to log why the period of idle time has occurred, this can be inputted straight away, during the downtime or even post the downtime if required.

Yes it does.

Work order information can be inputted manually or directly imported from a .CSV file.

This data includes the WO number, operations, machine names, estimated job time and start dates.

As with all parts of the FourJaw platform, this data is combined with the downtime and utilisation data to provide meaningful and actionable insights into your production process.

As a manufacturer, likely, you'll already be monitoring Work order times, Ops times and setup times, of course, this is all useful, however, it does not give you the big picture.

For instance, it doesn't identify and inform you of what improvements can be made to improve shop floor productivity.

Machine monitoring differs because it will give you real-time, actionable shop floor data such as:

- Top 5 downtimes, per factory, cell or machine

- Pareto plots

- Average setup time per part

- Downtimes and machine active times per work order

This information can be used to make decisions based on fact and not opinion.

Ready to

Learn More?

See how FourJaw's plug-and-play analytics can help you turn machine data into real productivity gains. What would you like to do next?