Machine Analytics, Installed In Minutes.

FourJaw works on ANY Machine, regardless of age or type

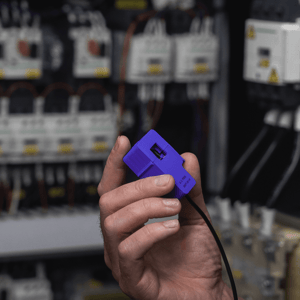

Clip the sensors to the machine's power cables.

Connect the MachineLink IoT device to WiFi and mains power.

Use data insights to start identifying and removing inefficiencies.

Manufacturing Analytics Made Simple

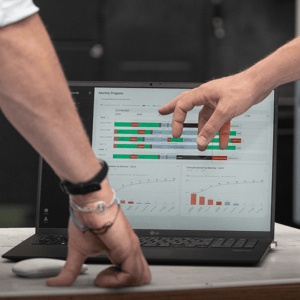

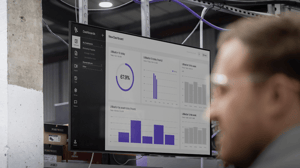

Monitor machine performance and utilisation as it happens, allowing for immediate action and continuous improvement.

Our system is compatible with any machine, regardless of age or brand, ensuring a seamless setup without the need for complex installations.

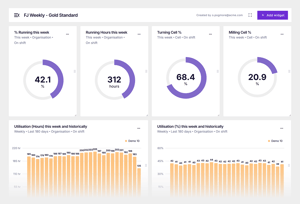

Track key performance indicators such as Utilisation, Overall Equipment Effectiveness (OEE), downtime reasons, and job progress to identify areas for optimisation.

Analyse energy consumption to reduce costs and support sustainable manufacturing practices.

FourJaw

Features

Enhance productivity across your factory floor. Whether your goal is to optimise processes, improve accuracy, or reduce costs, FourJaw provides the actionable insights to make it happen.

Production Utilisation

Pinpoint the main causes of machine downtime and their impact on costs and performance. Use Pareto analysis to focus on high-impact areas, enabling efficient corrective actions and optimised operations.

Production Timeline

Spot bottlenecks in real time with our Timeline View, and drill down to see exactly where production is stalling.

Energy Consumption Reports

Factories often waste energy unnecessarily, while facing increasing pressure to meet sustainability goals. FourJaw's sustainability features help you tackle both challenges at once.

What our customers say

"Now we use FourJaw we can see where we have capacity that we're not using"

"You may have been in the position where you think you need to buy another machine. Because you think you’ve got a capacity problem, but now we use FourJaw we can see where we have capacity that we're not using."

"If you’d asked me, before FourJaw, what the cycle times were, I genuinely would not have known"

"The data... facilitated conversations which were used to inform and educate operators, leading to a greater sharing of best practices, changed behaviours, and enhanced machine utilisation and productivity."

"A solution that is delivering real benefit from the top floor to the shop floor"

"The Armac Martin management team felt the business had more production capacity but had no quantifiable measure of where that capacity was. They felt that a machine monitoring solution would provide the answer and turned to FourJaw for support"

"We've seen a parts increase of 65%"

"Before FourJaw, a lot of our data was captured manually, paper forms, paper sheets. FourJaw has enabled us to identify where machines are underutilised, so we were getting quite empirical data driven evidence as to what we needed to do to improve performance in the machine shop."

"It’s has become an essential aspect of our production planning processes"

"Sometimes, especially with a new job, we estimate production time based on similar components, but now we can see instantly how long the job actually takes."

.png?width=70&name=Happy%20(5).png)

"FourJaw was an easy investment to make and a giant leap forward in our digitisation journey"

"It has been adopted as part of the culture of our organisation, improving efficiency and communication and providing objective data to inform production schedules, operational improvements and machine investment strategies."

Try an Interactive Guide

Get instant access to FourJaw’s Interactive Intro and see how it transforms manufacturing efficiency

View an interactive guide

Share your company details for instant access to an interactive guide to FourJaw.

- Manufacturing Challenges FourJaw Solves

Learn how FourJaw solves downtime, inefficiency, and visibility issues to boost results. - FourJaw’s Fast Installation Process

Learn how FourJaw’s plug-and-play technology makes installation simple and quick, getting going in no time. - Ways to Reduce Energy Waste

Explore how FourJaw helps identify energy inefficiencies, saving costs and reducing your carbon footprint.

Frequently Asked Questions

Can’t find the answer you’re looking for? Reach out to our customer support team.

Commonly collected data includes machine utilisation, downtime reasons, cycle times, and energy consumption. This data is used to monitor performance, identify inefficiencies, optimise workflows, and improve overall equipment effectiveness (OEE).

Where conventional systems might read any spindle movement as "productivity", FourJaw accurately detects genuine, money-making productivity. For example, FourJaw can detect when a CNC machine is cutting metal, by observing the rise in current usage during actual work.

This not only provides a more accurate measure of machine efficiency but also ensures consistency in data across all machines, facilitating better decision-making across your factory.

FourJaw captures downtime data through a combination of its MachineLink hardware and tablets mounted on the machines.

When a MachineLink detects downtime, it automatically prompts the operator via the tablet to select the reason for this downtime from a predefined list.

This process is quick and non-disruptive, designed to minimise interruption to the operator's workflow.

By simplifying the input method to just a few taps, FourJaw ensures that accurate downtime reasons are recorded with minimal effort, enabling a comprehensive analysis of machine productivity and downtime causes without impeding your operators.

Yes. Unlike traditional machine monitoring solutions, we designed our machine monitoring platform to be accessible, not only did we make it easy to install (minimising disruption to your factory floor) but we also made it affordable.

We offer monthly payment plans and you can install it yourself, so there are no high upfront installation costs often associated with traditional machine monitoring solutions