Building & Construction

Building & Construction

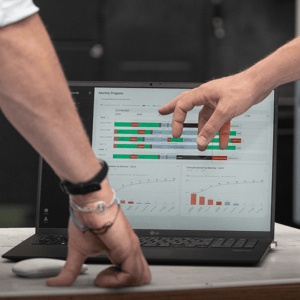

Keep production flowing, reduce delays, and ensure every unit meets specification with real-time factory visibility.

Build Smarter.

Deliver with Confidence.

Construction cycles can change quickly. Without accurate output data, it's difficult to plan capacity, forecast lead times, or manage labour efficiently.

FourJaw identifies the production bottlenecks, delays and micro-stoppages that limit throughput, enabling you to free up hours of productive time each week without investing in new equipment.

Installers and contractors rely on precise delivery dates. Lack of real-time visibility makes it difficult to manage bottlenecks before they affect customers.

FourJaw provides visibility of live performance data, helping you spot delays early, rebalance workloads, and give customers accurate lead times.

Compressors, dust extraction, large motors and cutting/processing machinery consume huge amounts of power, often without visibility of wasted energy, idle running or inefficiency.

With FourJaw, you can see when machines run idle, when extraction systems are active unnecessarily, and where energy consumption spikes, all in one place.

Read what energy savings and productivity gains Architectural Metal Systems achieved using FourJaw.

Are production challenges limiting your capacity?

Manufacturers of building and construction products operate in one of the most time-sensitive and specification-driven supply chains.

Even small delays can disrupt installation schedules, increase costs, and impact customer confidence.

FourJaw gives you a real-time view of machine utilisation, downtime and performance across every machine, old or new, enabling you to eliminate bottlenecks and unlock the capacity you already have.

.png?width=300&name=Window%20manufacturing%20(1).png)

If your factory ran 10% better tomorrow, what would it mean?

By increasing machine productivity by 10%, Listers now produce 250+ extra window frames every week, with no new machines or added labour.

Manufacturing Productivity

Starts Here.

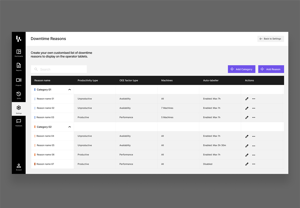

FourJaw's Features

Everything you need to streamline and optimise processes to grow your business.

Gain capacity by improving processes and removing bottlenecks.

Simplify planning and communication for a more efficient factory floor.

Cut energy waste, streamline processes, and shrink your carbon footprint.

Customer Testimonials

"FourJaw was an easy investment to make and a giant leap forward in our digitisation journey."

It has been adopted as part of the culture of our organisation, improving efficiency and communication and providing objective data to inform production schedules, operational improvements and machine investment strategies.

"In just a few short months, FourJaw has changed the way decisions are made at Listers and delivered productivity and sustainability gains that are already saving us thousands of pounds a week."

FourJaw has become the heartbeat of the business, enabling us to take a proactive and targeted approach to continuous improvement that benefits our people, customers and bottom line.

Read the case study

Ready to

Learn More?

See for yourself how FourJaw's production monitoring software can provide you with the factory intelligence you need to drive productivity, effortlessly.

Production Monitoring FAQs

Building and construction product manufacturers are increasingly turning to production monitoring systems to improve capacity, reduce downtime and stabilise delivery performance.

These FAQs explain how FourJaw works, the benefits it provides, and what to consider when evaluating solutions for your factory.

Yes. FourJaw is designed to work with any machine involved in the production of building and construction products — regardless of age, type or brand. This includes equipment used for manufacturing:

-

Doors and windows

-

Timber, aluminium, PVCu and composite products

-

Architectural metalwork and fabricated components

-

Sheet materials and panel systems

-

Framing and structural elements

-

HVAC components and ducting

-

Hardware, fittings and small-part assemblies

-

Modular and off-site construction elements

By capturing real-time utilisation, downtime and performance data across all these machines, FourJaw provides full-factory visibility and helps you unlock hidden capacity without new equipment.

Most building-product factories run a mix of machinery and high product variation, which often hides bottlenecks.

A production monitoring platform like FourJaw gives real-time visibility of machine utilisation and downtime, helping you identify slow-running equipment, inefficient changeovers and avoidable stoppages.

By removing these hidden constraints, manufacturers typically unlock 10–20% additional capacity without investing in new machines or labour.

Yes. FourJaw is designed to connect to any machine, regardless of age, type or brand, including saws, routers, edge-banders, presses, welders and older CNCs with no native data output.

This makes it ideal for building-product manufacturers with mixed or legacy equipment, enabling full-factory visibility without expensive upgrades.

FourJaw tracks the KPIs that matter most in this sector, including machine utilisation, downtime (planned and unplanned), changeover time, run-time efficiency, energy consumption, and job-level performance.

These manufacturing metrics support lean manufacturing, help reduce waste and improve productivity across fabrication and assembly lines.

Many construction-product factories operate high-power equipment, extraction systems and compressors. FourJaw highlights idle running, excessive power use and energy spikes across machines and shifts. This helps teams switch equipment off when not needed, cut unnecessary running hours and lower electricity consumption, improving margins and supporting sustainability targets.