Production downtime tracking software

Production downtime tracking software

Automatically track, analyse, and reduce machine downtime with real-time data from your factory floor.

Production Tracking.

Made Simple.

Unplanned downtime is one of the biggest hidden costs in manufacturing. Yet many factories still rely on manual logs, operator input, or incomplete machine data to understand why production stops.

FourJaw provides production downtime tracking software that automatically captures machine activity, giving manufacturers a clear, real-time view of where time is being lost and why.

How FourJaw helps track Production Downtime.

FourJaw automates production downtime collection by connecting your machines, operators, and data in one simple platform.

FourJaw connects directly to your machines to detect when production stops.

3 Simple steps to get accurate production data.

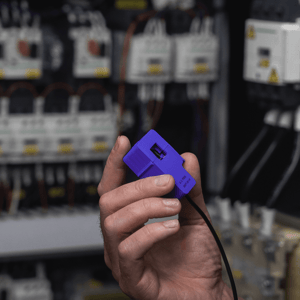

Clip the sensors to the machine's power cables. Zero integration with the PLC or control is required.

Connect the MachineLink IoT device to WiFi and mains power. Your machines begin sending live production data instantly.

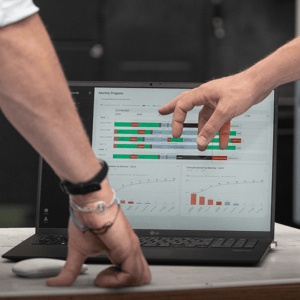

Use data insights to start identifying and removing inefficiencies. Identify waste, target improvements and measure impact with real data.

Downtime Data & Reporting features.

FourJaw’s manufacturing production tracking software provides clear dashboards and reports that show:

-

Total downtime by machine, shift, or reason

-

Trends over time

-

The biggest contributors to lost production

This allows teams to move beyond “why did we miss target?” to “what should we fix first?”

Production Timeline

Identify production bottlenecks in real-time with our Timeline View, and drill down to see exactly where production is stalling and capacity is being lost.

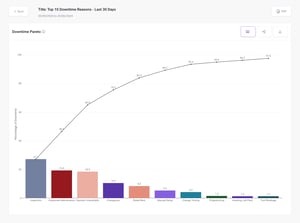

Downtime Reasons

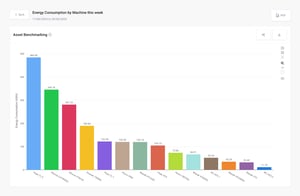

Energy Consumption Reports

Factories often waste energy unnecessarily, while facing increasing pressure to meet sustainability goals. FourJaw's machine monitoring system's sustainability features help you tackle both challenges at once.

Customer Testimonials

"FourJaw has delivered a significant and sustained improvement in the productivity levels we're getting from our manufacturing centres."

Monitoring downtime, eliminating the various causes of waste in our processes, and deploying colleagues to where they are needed most has helped achieve a 30 per cent overall increase in uptime.

“You may have been in a position where you think you need to buy another machine".

Because you think you’ve got a capacity problem, but now that we use FourJaw, we can see where we have capacity that I'm not using. FourJaw is the tool we use to maintain a ‘drumbeat’ of improvement and create a healthy, competitive environment to keep trying to do better.

“We’ve removed all back orders and are now in a position to deliver orders on time for customers worldwide.”

This is a tangible benefit of our unprecedented increase in machine productivity, and we’ve also improved staff retention with a calmer, less stressful working environment where operators have the autonomy to get on with the job.

See for yourself how

Manufacturing Productivity

Starts Here.

Use cases from our Manufacturing community.

Leading manufacturer of windows & doors improves productivity by 10%

From 19% to 47% - How this factory Transformed Machine Productivity

Fernco transforms factory insight and productivity

Aerospace Manufacturer, AVPE Systems increases factory uptime by 30%

Frequently Asked Questions.

As demonstrated a little further up this page, downtime is tracked by connecting software directly to machines via our MachineLink IoT device to detect when production stops or slows below expected levels. This prompts operators to input the relevant downtime at the touch of a button, ensuring consistent, real-time data across shifts and machines.

The short answer is, any.

Production downtime tracking software, such as FourJaw can capture both planned and unplanned downtime, including:

- Machine breakdowns

- Setup and changeovers

- Material shortages

- Operator delays

- Quality issues

When a customer starts to use FourJaw to track their downtime, they can choose their downtime categories to ensure they are relevant to their manufacturing processes. However, we always recommend keeping the list as concise as possible, as good categorising helps manufacturers identify recurring problems and prioritise improvement actions quickly.

OEE is often used as a 'generic' term to describe things like production and machine monitoring.

However, downtime directly impacts the Availability component of Overall Equipment Effectiveness (OEE) and accurate downtime tracking ensures OEE calculations are based on real machine behaviour, giving manufacturers a reliable baseline to measure improvements and reduce lost production time.

Not if you use FourJaw!

Modern downtime tracking software, such as FourJaw is designed for quick deployment in live manufacturing environments. Systems such as ours can be installed with minimal disruption, require little operator training, and can scale easily across multiple machines and sites.

There are a few ways to track production downtime.

Some manufacturers still rely on manual, paper-based data collection methods. They may seem the cheapest and easiest option, but people often forget to account for the time it takes to capture the information and do something meaningful with it. Manual data capture is also often outdated and inaccurate to be of any use.

However, more and more manufacturers track production downtime by using software (like FourJaw) that automatically collects data from machines when production stops. This removes the need for manual downtime logs and provides consistent visibility across shifts, machines, and production lines.