Drive Sustainability with Data.

Not Guesswork.

Factories often waste energy unnecessarily while facing increasing pressure to meet sustainability goals. FourJaw's sustainability features help you tackle both challenges at once.

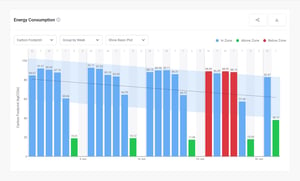

Identify inefficiencies and reduce energy consumption across your machines.

Track and lower emissions at every level, from individual machines to the whole factory.

Remove unproductive and inefficient processes that waste energy to optimise running costs.

Energy & Sustainability features

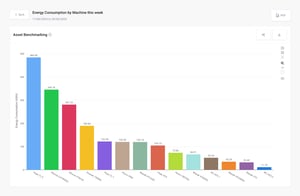

Energy Consumption Reports

Identify energy-intensive processes and optimise energy usage. Our detailed Energy Consumption Reports give you crystal-clear visibility from the factory floor to individual machines.

Carbon Footprint Reports

Identify your biggest carbon emitters down to individual machine level. Improve your environmental credentials and ensure you are complying with regulatory or contract requirements.

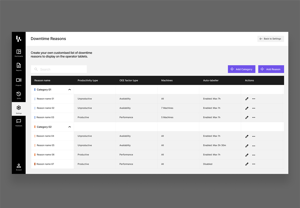

Energy Cost Reports

Understand energy costs for each machine, line, or factory. Make informed decisions on whether to replace energy-intensive assets where potential energy-saving opportunities are identified.

FourJaw's Features

Everything you need to streamline and optimise processes to grow your business.

Streamline processes to cut costs, boost speed, and enhance efficiency.

Simplify planning and communication for a more efficient factory floor.

Cut energy waste, streamline processes, and shrink your carbon footprint.

Frequently Asked Questions

Here's some of the most common questions we get asked from manufacturers who are looking to install machine monitoring software within their manufacturing operations.

According to MakeUK, 90% of emissions from manufacturers come from the manufacturing process itself. This makes monitoring energy and increasing productivity key to achieving net zero while helping to save money.

Smart technology can help identify energy consumption patterns, set baselines and targets, identify efficiency improvement, inform investment priorities to name a few.

Here's a useful article that looks at how technology can help manufacturers improve sustainability and achieve net zero.

Ready to

Learn More?

See how FourJaw's plug-and-play analytics can help you turn machine data into real productivity gains. What would you like to do next?