Make investment decisions backed by real production data—not assumptions.

Understand how production issues affect output, delivery, and ultimately revenue.

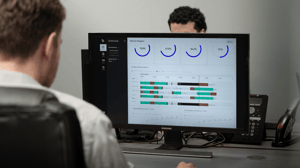

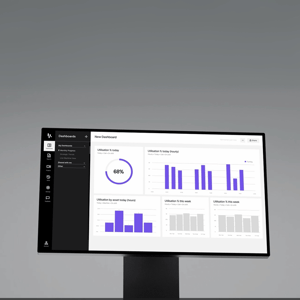

See how long jobs really take and how resources are being used.

Real-Time Insight. Smarter Financial Decisions.

Finance teams gain real-time and historical visibility into factory performance, helping identify opportunities to reduce waste, improve productivity, and boost profitability.

With accurate, actionable data at your fingertips, you can better align operational efficiency with financial outcomes.

Our monthly, pay-as-you-go pricing plan model means you don’t have to raise finance to realise productivity benefits.

Cost Reduction & Operational Efficiency

By identifying and reducing unproductive downtime, you can increase output without increasing overhead. This improves asset utilisation, lowers the effective hourly rate, and boosts contribution margins, enabling you to get more from your existing resources.

Optimise Resource Allocation and Inventory Management

By analysing real-time production data, finance teams gain visibility into how capacity aligns with demand, enabling smarter decisions around cash flow and resource allocation.

Improve inventory management with accurate, real-time insights on production rates and material usage, helping you reduce excess stock, lower carrying costs, and free up working capital.

.png?width=300&name=Machined%20Billet%20(1).png)

Confident CapEx Decisions

Factory investment decisions shouldn’t rely on guesswork. FourJaw provides real-time and historical data so you can justify CapEx with confidence—using facts, not assumptions.

Track ROI over time to ensure new investments are delivering the performance and value you expected.

Factory Intelligence.

Made Simple.

The Results:

- Machine Utilisation Increase - hitting a record for asset utilisation

- Understanding the true time a job takes

- Being able to quote more accurately to improve profitability

- Driving a friendly, competitive culture across the shop floor

- Supporting a culture of Continuous Improvement

- Guided decisions for staff and equipment investments

Manufacturing Success Stories.

Leading manufacturer of windows & doors improves productivity by 10%

From 19% to 47% - How this factory Transformed Machine Productivity

Fernco transforms factory insight and productivity

Aerospace Manufacturer, AVPE Systems increases factory uptime by 30%

Ready to

Learn More?

See how FourJaw's plug-and-play analytics can help you turn machine data into real productivity gains. What would you like to do next?