About Hydrafeed

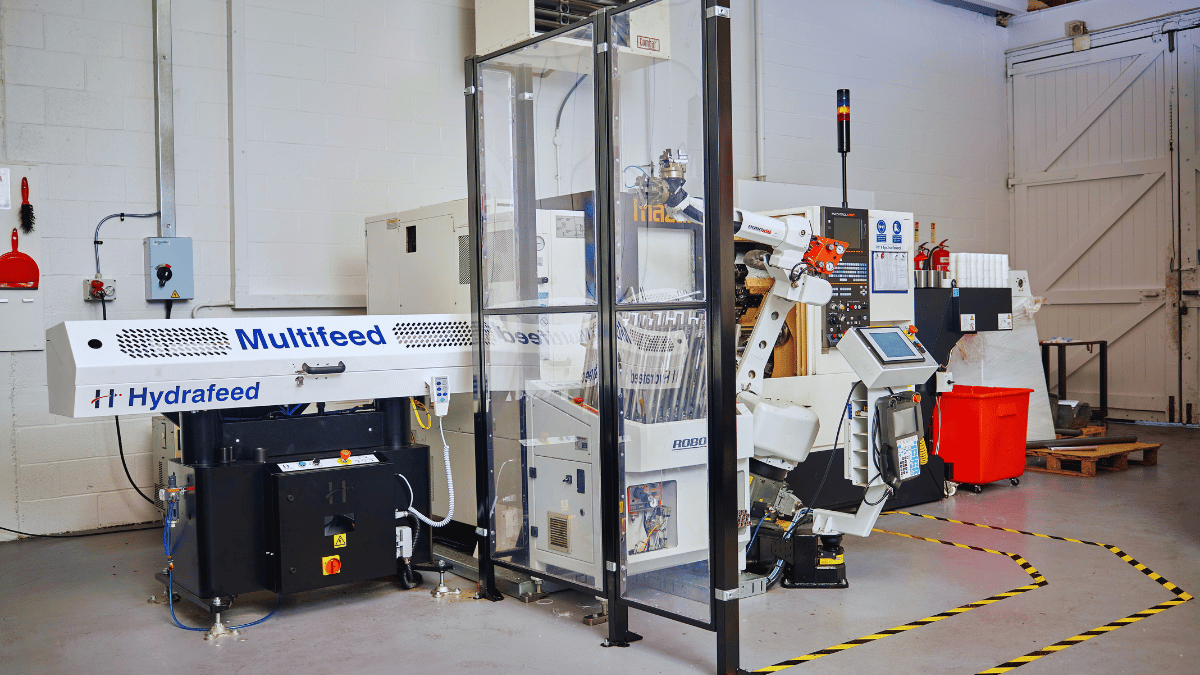

Hydrafeed is a leading manufacturer of automation equipment for CNC applications and a subcontract supplier to the aerospace industry.

Based in Milton Keynes, Hydrafeed employs 50 people and 19 milling and turning machines to produce Barfeed and machine tool automation products for CNC machine users and several of the world’s most prestigious OEMs.

"We had a strong business before FourJaw but limited visibility of shop floor operations. We've addressed that with FourJaw, and the response from management and machine operators has been positive. Everyone has clarity of what needs achieving and has bought into our plans to improve productivity and profitability."

Results

Supporting Business Growth, Process Improvement and Sustainability

Since installing FourJaw's machine monitoring solution on the factory floor, Hydrafeed has gained real-time visibility into its factory operations, enabling it to meet growing production demand with its existing workforce and achieve energy savings worth more than £17,000 a year within a month of implementing the technology.

Hydrafeed installed FourJaw’s plug-and-play platform on 14 of its machines in September 2023, enabling it to automatically recognise when they were productive, record reasons for downtime, generate a digital work schedule to guide factory operations and improve communication with machine operators.

FourJaw’s platform has provided Hydrafeed with a real-time understanding and visualisation of its factory data, enabling it to establish a production efficiency benchmark and a detailed account of energy usage. This has already improved the day-to-day management of manufacturing operations and provided a clear understanding of where Hydrafeed can achieve productivity and sustainability gains.

"FourJaw has been a revelation. We’ve already reduced energy consumption and identified further opportunities for improvement. We know precisely what machines are running and when, what they’re working on, how much energy they use, how long each job takes, and where time is being lost and why."

Optimising Production Processes

During the first five weeks of using FourJaw, Hydrafeed was able to generate the same output in its milling cell with four fewer machines, allowing the reallocation of machine operators to its turning cell, where it has boosted utilisation by 30 per cent.

.png?width=1752&height=561&name=image%20(7).png)

Image: Utilisation in the turning cell was increased by 30% after Hydrafeed made changes to their processes off the back of FourJaw data.

Hydrafeed identified further opportunities to reduce energy usage through more efficient machine operation within days of installation. The energy savings Hydrafeed has already identified will deliver a complete return on its investment in FourJaw.

"We were thrilled to welcome Hydrafeed to FourJaw's growing community of manufacturers and pleased to see our technology provide an almost immediate return on investment. We see manufacturers who are proactively using FourJaw’s technology, can typically achieve productivity gains of anywhere between 10-20% which can increase output capacity by as much as 30%, so we are excited to see what more Hydrafeed will achieve with FourJaw.”