Manufacturing Data Collection Software

Manufacturing Data Collection Software

Connect your machines, operators, and data in one simple platform.

Take Control of Your Factory Floor

FourJaw gives manufacturers the visibility and insights needed to boost productivity, reduce downtime, and hit delivery targets without guesswork.

Get a personalised demo with one of our team.

Core Software Capabilities

FourJaw automates production data collection by connecting your machines, operators, and data in one simple platform.

By turning live production data into clear, actionable insights, FourJaw helps manufacturers run smarter, faster, and more efficient factories.

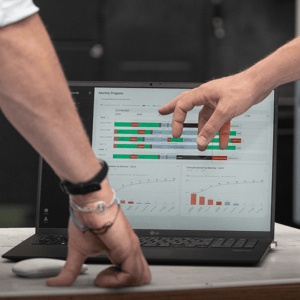

FourJaw gives you real-time visibility and control, with live machine monitoring and shop floor dashboards that can be accessed anywhere

Get real-time production data that is always within reach. Monitor live data from anywhere, at any time.

Get real-time production data that is always within reach. Monitor live data from anywhere, at any time.

Production data collection. Designed for all.

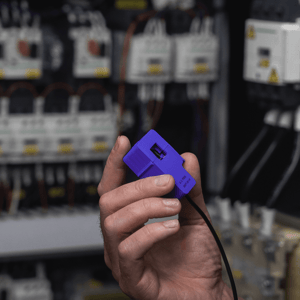

Clip the sensors to the machine's power cables. Zero integration with the PLC or control is required.

Connect the MachineLink IoT device to WiFi and mains power. Your machines begin sending live production data instantly.

Use data insights to start identifying and removing inefficiencies. Identify waste, target improvements and measure impact with real data.

FourJaw data collection

software features.

Operators shouldn’t have to fill out paper forms or key in Excel data.

Whether you want to reduce unplanned downtime, unlock hidden capacity, or improve delivery performance, FourJaw's automated data collection gives you the tools to make it happen.

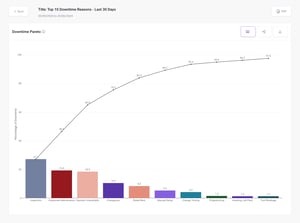

Downtime Reasons

Production Timeline

Identify production bottlenecks in real-time with our Timeline View, and drill down to see exactly where production is stalling and capacity is being lost.

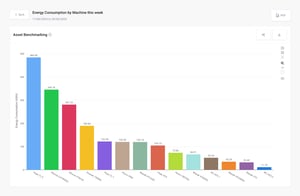

Energy Consumption Reports

Factories often waste energy unnecessarily, while facing increasing pressure to meet sustainability goals. FourJaw's machine monitoring system's sustainability features help you tackle both challenges at once.

Customer Testimonials

"FourJaw has delivered a significant and sustained improvement in the productivity levels we're getting from our manufacturing centres."

Monitoring downtime, eliminating the various causes of waste in our processes, and deploying colleagues to where they are needed most has helped achieve a 30 per cent overall increase in uptime.

“FourJaw is helping us move towards 4.0 based on our S&OP.”

It allows us every month to analyse with the directors to see our strengths and weaknesses and plan forward based on what we find. From a continuous improvement point of view, we now have concrete evidence of where to focus our energy, helping with costings, budgeting and machine utilisation.

“We’ve removed all back orders and are now in a position to deliver orders on time for customers worldwide.”

This is a tangible benefit of our unprecedented increase in machine productivity, and we’ve also improved staff retention with a calmer, less stressful working environment where operators have the autonomy to get on with the job.

FourJaw is Different

Most automated data collection systems are complex and expensive to install. FourJaw isn't.

| Traditional Solutions | FourJaw | |

|

Plug & Play Installation |

||

|

Monthly Subscription |

||

|

No Large Upfront Costs |

||

|

ROI in Weeks, Not Months |

||

|

Works on Any Machine, Regardless of Age or Brand |

||

|

Regular Security & Feature Updates Included |

||

|

Productivity & Energy Monitoring features |

Plug & Play Installation

Monthly Subscription

No Large Upfront Costs

ROI in Weeks, Not Months

Works on Any Machine, Regardless of Age or Brand

Regular Security & Feature Updates Included

Productivity & Energy Monitoring features

See FourJaw In Action

Complete the form to request a personalised demo and discover the full potential of your factory.

Manufacturing Success Stories.

Leading manufacturer of windows & doors improves productivity by 10%

From 19% to 47% - How this factory Transformed Machine Productivity

Fernco transforms factory insight and productivity

Aerospace Manufacturer, AVPE Systems increases factory uptime by 30%

Frequently Asked Questions

Manufacturing data collection software connects machines, operators, and data to give you visibility and control of your factory floor. It helps track performance in real time, reduce downtime, improve throughput, and make data-driven decisions that boost efficiency.

Read how manufacturers have benefited from our production software here.

Unlike complex MES or ERP systems, FourJaw is designed to be simple to deploy and easy to use on the shop floor. It complements existing systems by providing live production data and actionable insights that most ERP and MES platforms can’t deliver.

FourJaw's manufacturing production software is designed for use on all types of manufacturing equipment, including.

- CNC machines

- Lathes & milling machines

- Presses & injection moulding machines

- Assembly lines

- Fabrication equipment

Generally, if it has an electrical current, FourJaw can tell you how productive it is (and how much energy it uses).

No. FourJaw’s hardware and cloud-based platform work with your existing machines—old or new. It’s designed to be plug-and-play, meaning you can be up and running without major investment in new infrastructure.

This means even machinery that's decades old can be upgraded to a "smart machine," enabling you to gain insights into the productivity of your equipment.

Absolutely! Our manufacturing production software isn’t just for large manufacturers. Small and Mid-sized companies benefit just as much by gaining visibility into machine utilisation, reducing bottlenecks, and improving operational efficiency.

Take a look at our case studies to see how our machine monitoring system is helping manufacturers of all sizes improve their manufacturing processes.