Factory Digitalisation Made Easy

Factory Digitalisation Made Easy

Digitise your production process effortlessly. Get live machine data to make smarter, faster decisions.

Digitisation Starts with Machine Monitoring

Factories that digitise without machine monitoring are missing the foundation for real improvement. FourJaw provides the real-time production data your ERP, MES, and automation need to drive efficiency, reduce costs, and increase profitability.

Fast ROI. Zero hassle.

Factories often begin their digitisation journey with production monitoring, as it delivers a fast ROI without disrupting existing workflows.

However, traditional production monitoring has been costly and complex—until now. FourJaw simplifies the process with a plug-and-play solution that works on any machine with virtually no downtime.

A Digitisation Success

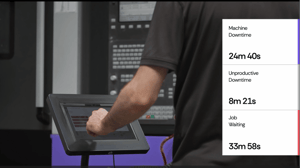

Their ERP Said a Job Took Too Long, FourJaw Showed them why

As Sterling Machining found, data without context is just noise. FourJaw connects the dots between machine performance, productivity, and profitability.

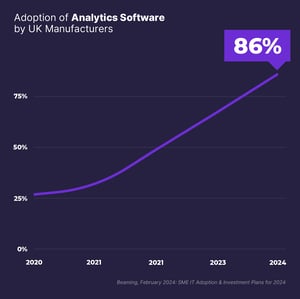

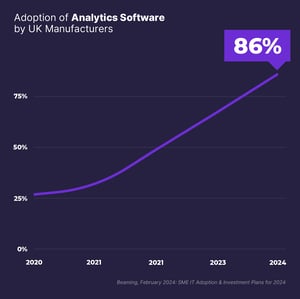

86% of UK Manufacturers Are Using Analytics.

Manufacturers that track their production data don’t just keep up—they pull ahead. With analytics, you can see where time is lost, optimise processes, and make better decisions every day. FourJaw gives you those insights without the hassle.

Explore our Interactive Guide

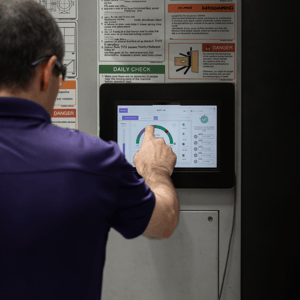

Install in minutes

FourJaw works on ANY Machine, regardless of age or type.

Clip the sensors to the machine's power cables.

Connect the MachineLink IoT device to WiFi and mains power.

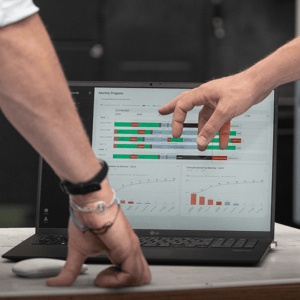

Use data insights to start identifying and removing inefficiencies.

Factory Digitisation Success Stories.

Leading manufacturer of windows & doors improves productivity by 10%

From 19% to 47% - How this factory Transformed Machine Productivity

Fernco transforms factory insight and productivity

Aerospace Manufacturer, AVPE Systems increases factory uptime by 30%

The time to Digitise is now

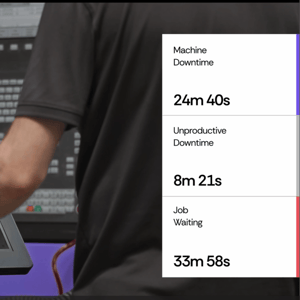

Manual processes slow you down. Digitisation speeds you up.

FourJaw captures real-time production data automatically—no more manual entries or guesswork.

With instant insights into machine performance and downtime, you can make faster decisions, reduce inefficiencies, and boost output.

Ready to

Learn More?

See how FourJaw's plug-and-play analytics can help you turn machine data into real productivity gains. What would you like to do next?

Frequently Asked Questions

Likely, yes! FourJaw is trusted by manufacturers across industries, including automotive, food production, oil & gas, chemicals, and more.

You’ll gain real-time visibility into machine utilisation, downtime reasons, OEE (Overall Equipment Effectiveness), and job tracking performance.

No. FourJaw offers a flexible monthly subscription model, so you can cancel anytime if it’s not the right fit for your business.

No. FourJaw works with your existing machines using non-invasive, plug-and-play hardware—no costly upgrades or modifications needed.

FourJaw is a plug-and-play solution that works with any machine, regardless of age, model, or brand—no complex integrations or downtime required.