Start with a Quick Video

Stay ahead of downtime, increase efficiency, and gain full visibility of your factory floor with our powerful machine monitoring system.

Seen enough? Get a personalised demo with one of our team.

Machine Monitoring. Designed for all.

One platform. Any machine.

FourJaw's machine monitoring system is designed to provide complete factory visibility across all machines in a single platform.

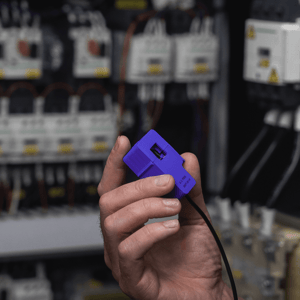

Clip the sensors to the machine's power cables.

Connect the MachineLink IoT device to WiFi and mains power.

Use data insights to start identifying and removing inefficiencies.

FourJaw

Features

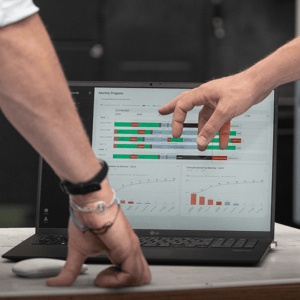

Designed for manufacturers, our easy-to-use system delivers real-time insights into machine performance, helping you reduce production bottlenecks, optimise capacity, and drive continuous improvement.

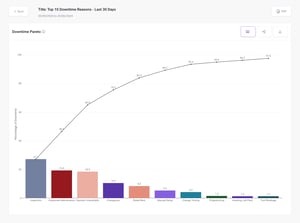

Downtime Reasons

Production Timeline

Identify production bottlenecks in real-time with our Timeline View, and drill down to see exactly where production is stalling and capacity is being lost.

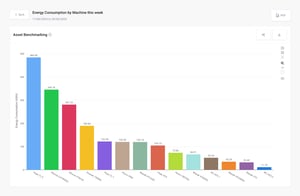

Energy Consumption Reports

Factories often waste energy unnecessarily, while facing increasing pressure to meet sustainability goals. FourJaw's machine monitoring system's sustainability features help you tackle both challenges at once.

FourJaw is Different

Most machine monitoring systems are complex and expensive to install. FourJaw isn't.

| Traditional Solutions | FourJaw | |

|

Plug & Play Installation |

||

|

Monthly Subscription |

||

|

No Large Upfront Costs |

||

|

ROI in Weeks, Not Months |

||

|

Works on Any Machine, Regardless of Age or Brand |

||

|

Regular Security & Feature Updates Included |

||

|

Productivity & Energy Monitoring features |

Plug & Play Installation

Monthly Subscription

No Large Upfront Costs

ROI in Weeks, Not Months

Works on Any Machine, Regardless of Age or Brand

Regular Security & Feature Updates Included

Productivity & Energy Monitoring features

Recognised By Industry

See FourJaw In Action

Share your company details to request a personalised demo and discover the full potential of your factory.

Frequently Asked Questions

A machine monitoring system is a real-time data collection and analysis tool that helps manufacturers track machine performance, utilisation, and downtime. It provides production insights to improve efficiency, reduce waste, and maximise productivity on the shop floor.

Read how manufacturers have benefited from our system here.

The system connects machines using non-invasive sensors that link to our MachineLink IoT hardware.

When the MachineLink detects machine downtime, it automatically prompts the operator via the FourJaw tablet to select the reason for the downtime from a predefined list (customisable by you).

The data is then displayed on FourJaw's web-based dashboard, allowing managers to make data-driven decisions in real-time.

FourJaw's machine monitoring system is designed for use on all types of manufacturing equipment, including.

- CNC machines

- Lathes & milling machines

- Presses & injection molding machines

- Assembly lines

- Fabrication equipment

Generally, if it has an electrical current, FourJaw can tell you how productive it is (and how much energy it uses).

Absolutely. We've tailored our machine monitoring system to ensure it's usable by manufacturers across the board, which includes ensuring compatibility with machines of every age, make, or model.

This means even machinery that's decades old can be upgraded to a "smart machine," enabling you to gain insights into the productivity of your equipment.

Absolutely! Machine monitoring isn’t just for large manufacturers. Small and Mid-sized benefit just as much by gaining visibility into machine utilisation, reducing bottlenecks, and improving operational efficiency.

Take a look at our case studies to see how our machine monitoring system is helping manufacturers of all sizes improve their manufacturing processes.