Total Factory Visibility (TFV)

See every machine. Improve every outcome.

A clear path to ongoing operational excellence, productivity, and sustainability.

Introduction

Manufacturers are facing tough economic times and rising costs. Many are addressing this issue by making more informed decisions, implementing continuous improvement initiatives, and adopting new technologies like AI and robotics. All of these initiatives rely on data.

But many factories still collect data slowly and manually, or struggle with complex, inconsistent data from connected machines. They don’t have a full, real-time view of what’s happening.

The most effective way to utilise data in a factory is through Total Factory Visibility (TFV), a comprehensive, real-time view of your entire factory’s performance.

Instead of being overwhelmed by data, TFV focuses on collecting "Fundamental Data" (such as machine utilisation, downtime and energy consumption) from all machines. This enables everyone, from the factory floor to management, to make informed choices and drive targeted improvements.

The result? Higher utilisation, faster decisions, lower energy waste, and a clearer path to profit.

Find out more and how to achieve TFV in this article or download the complete guide today.

The challenge: A disconnected reality

Manufacturing has faced more than its share of disruption, from global pandemics to supply chain shocks and rising energy costs. While confidence is recovering, UK manufacturing growth is forecast to stay weak into 2026 as inflation and skills shortages continue to weigh on productivity.

In response, manufacturers are doubling down on automation, analytics and AI technologies that depend on robust, accessible data. According to Make UK’s most recent survey data, 71% of manufacturers now plan to invest in technology to tackle costs. Technology depends on data.

Figures from IBM suggest that the average factory generates about 1 terabyte of production data, the equivalent of 6.5 million document pages and four times the storage capacity of a typical laptop, every single day. This stream of data offers the potential for deep and valuable insights into every part of the manufacturing process, but less than 1% of it is analysed.

Why? Because it’s trapped in legacy systems, disconnected formats, or according to the Manufacturing Leadership Council, in 70% of cases manual data collection using clipboards and spreadsheets.

Manual data is slow, incomplete and prone to error. It leaves managers estimating, operators frustrated, and finance teams making investment decisions without knowing their factory’s true capacity.

The manufacturers who win will cut through this complexity with a single, real-time view of their entire factory.

That’s Total Factory Visibility.

Download the guide to TFV

What is Total Factory Visibility (TFV)?

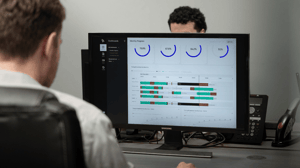

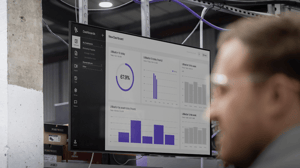

TFV means seeing your entire production environment in one place. Every machine, line and shift, in real time.

It combines objective machine data (run/stop, energy, utilisation) with operator insight (downtime reasons and context) to create a single, trusted source of truth. Everyone, from factory floor teams to CI specialists to finance, works from the same accurate, shared data.

Instead of inspecting machines one by one or waiting weeks for reports, manufacturers with TFV can view the factory as a connected system, respond instantly to issues, and continuously feed improvement ideas back into operations.

See the impact of TFV on manufacturers

The data fundamentals of TFV

The key to achieving Total Factory Visibility is focusing on a few critical, comparable metrics that every machine can provide.

We call this Fundamental Machine Data, the essential data signals that show where productivity is gained or lost.

01. Machine Utilisation

Know when each asset is actually running, making parts and earning money.

Continuous machine utilisation data exposes idle time, small stops, bottlenecks and habits that erode output, helping you unlock hidden capacity without new investment.

02. Machine Downtime (with reasons)

Capture every planned and unplanned stop automatically, and ask operators for the cause when a stop occurs.

Real-time alerts prevent minor stoppages from becoming lost shifts, while weekly Pareto reviews help you tackle the biggest causes of lost time first.

03. Machine-Level Energy

Track energy use at the machine level to understand true operating costs.

Spot spikes, out-of-hours usage or deteriorating performance, and justify replacements or maintenance with clear ROI data.

This also supports ISO 50001 by identifying Significant Energy Users (SEUs) and defining Energy Performance Indicators (EPIs).

04. Machine-Level Profitability

Combine utilisation, downtime and energy data to understand each machine’s contribution to margin.

Quote accurately, eliminate unprofitable jobs, and prioritise investments that truly improve financial performance.

Download the complete guide to TFV

The benefits of total factory visibility

1. Boost productivity and efficiency

TFV gives teams real-time visibility into machine status and downtime, enabling rapid, targeted improvement.

-

Find and fix bottlenecks quickly with live machine and line status.

-

Increase utilisation to gain more output from existing assets, cutting lead times and overtime.

-

Systematically reduce downtime by identifying and fixing recurring stoppage causes.

Result: More productive hours from the assets you already own.

2. Make data-driven decisions and maximise profit

Real-time, consistent factory data enables faster and more confident decisions.

-

Compare performance objectively across machines, shifts or sites.

-

Optimise resource allocation by identifying low-profit or underperforming assets.

-

Quantify ROI by turning utilisation, downtime and energy losses into financial figures.

High utilisation means achieving the same output with fewer machines or shifts, avoiding unnecessary capital spend and cutting overtime costs.

Tracking job times vs planned times also helps refine quoting, improve scheduling and protect margins.

Result: Smarter, evidence-based decisions that boost profitability.

3. Achieve sustainability and energy savings

Sustainability isn’t just a goal — it’s a measurable outcome of TFV.

-

Targeted energy reduction: Identify high-consumption machines and processes.

-

Prevent waste: Detect power use during idle periods and reduce unnecessary load.

-

Simplify compliance: Generate accurate data for ISO 50001 reporting.

Continuous monitoring drives both environmental and financial efficiency — reducing your carbon footprint while improving your bottom line.

Result: Lower energy costs, less waste, and measurable sustainability gains.

TFV Impact

"FourJaw has delivered a significant and sustained improvement in the productivity levels we're getting from our manufacturing centres."

Monitoring downtime, eliminating the various causes of waste in our processes, and deploying colleagues to where they are needed most has helped achieve a 30 per cent overall increase in uptime.

“FourJaw is helping us move towards 4.0 based on our S&OP.”

OEE increased 28% in 12 months, and from a continuous improvement point of view, we now have concrete evidence of where to focus our energy, helping with costings, budgeting and machine utilisation.

Your path to total factory visibility

Achieving TFV is a positive, manageable shift, a structured journey from disconnected data to complete, real-time insight.

In this section, we provide a practical roadmap based on proven best practice and FourJaw’s experience working with more than 150 manufacturers.

Objective: Understand your current state and define what success looks like.

-

Map how production data currently flows — manual, spreadsheets, or systems.

-

Identify pain points: downtime, lack of visibility, poor utilisation, energy waste.

-

Engage cross-functional teams (operators, CI, finance, leadership).

-

Set SMART goals: e.g., “Reduce unplanned downtime on Line A by 15% within six months.”

-

Use Value Stream Mapping (VSM) to identify where data gets stuck.

This phase ensures everyone understands the ‘why’ behind TFV and is aligned around measurable outcomes.

Objective: Pick the right technology and define a pilot with clear ROI.

-

Select a platform that connects to any machine, regardless of age or brand.

-

Ensure it can automatically capture utilisation, downtime and energy data.

-

Define a pilot area (one line, cell or process) where data gaps are most painful.

-

Involve an engaged team that will champion the change and share feedback.

A focused pilot delivers early success stories and helps refine your rollout strategy.

Objective: Connect, collect and show results quickly.

-

Install sensors and connect machines to your TFV platform (e.g., FourJaw’s plug-and-play hardware).

-

Configure dashboards for the key data points identified in Phase 1.

-

Train operators and managers on interpreting and using data.

-

Review data weekly, celebrate quick wins, and share results internally.

Early wins — such as reduced downtime or increased uptime — build momentum and confidence across the business.

Objective: Extend TFV across the factory and embed it into daily operations.

-

Apply pilot lessons to wider rollout — line by line or department by department.

-

Standardise data collection methods and reporting templates.

-

Assign internal champions to lead adoption and continuous improvement.

-

Integrate TFV data with ERP or BI systems for enterprise-wide insight.

Result: A factory-wide, real-time view that connects people, machines and decisions — all speaking the same data language.

Complete guide

to Total Factory Visibility.

The future of productive manufacturing

In today’s competitive, unpredictable landscape, Total Factory Visibility is essential.

It turns fragmented, reactive operations into a seamlessly integrated, intelligent production environment.

With TFV, you can:

- Gain real-time, holistic insight across your factory.

- Empower every role to make better, faster decisions.

- Improve utilisation, reduce energy waste and maximise profit.

Key takeaways

-

Assess and Define Goals: Before any new tech implementations, understand your current data setup (old and new machines, how data is collected). Talk to everyone to identify key issues (lack of visibility, downtime, high energy costs). Turn these into specific, measurable goals (e.g. "reduce unplanned downtime by 15% in six months").

-

Start with a Pilot: Don’t try to roll out TFV everywhere at once. Choose a focused pilot project to prove its value. Pick an area you feel may have a problem, engage staff, and identify potential for quick wins. This helps your team get comfortable and refines your strategy. For example, if one cell or production line has significant downtime, focus your pilot there, track improvements, and use that success to build momentum.

-

Scale Systematically: Once your pilot shows clear results, expand TFV across the rest of the factory. Apply all lessons learned from the pilot (tech setup, training, cultural buy-in) to the wider rollout. Expand in phases (department by department, line by line) to maintain stability. Standardise data collection and reporting. Finally, integrate your TFV data with other enterprise systems, such as ERP and supply chain management, to create a fully connected digital system.

The future factory is visible, connected and data-driven. And the path to get there starts with your first pilot project.

Tips and FAQs

Check out some of our top tips and answers to frequently asked questions about TFV.

Run a pilot on one production line or cell with clear pain points. Capture utilisation, downtime and energy data, then share results weekly to prove ROI.

-

Understand Your Current Setup and Problems: Begin by examining your existing data systems closely, identifying key issues (such as being unable to monitor progress or experiencing unexpected machine shutdowns), and establishing clear, measurable goals. Consider using the DMAIC framework, part of the Lean Six Sigma method, to guide this.

-

Data Integration: Select the technology that best aligns with your end goal. Begin with a small, focused pilot project in an area where problems are clear, and quick, measurable wins are possible to prove its value. The PDCA (Plan-Do-Check-Act) model supports this.

-

Piloting TFV Technology: Implement the technology in the pilot area, connect systems, and set up data collection. Explain, engage and train employees to get buy-in and iron out any initial issues. Show quick, tangible results to build confidence and support.

-

Scale and Expand: Once the pilot is successful, gradually roll out TFV across the entire factory. Ensure data collection, reporting, and feedback are consistent between the factory floor and top floor, and integrate TFV data with other business systems.

-

Improves Operational Efficiency: TFV helps identify and resolve issues that negatively impact operations and machine utilisation — providing staff with the insight to reduce unproductive downtime by pinpointing the causes of stoppages, enabling corrective action.

-

Informed, Data-Driven Decisions: Consistent, clean and accurate real-time data enables fair comparisons of performance, helps you utilise resources effectively, and creates opportunities to increase profit from each machine.

-

Sustainability and Energy Savings: TFV provides detailed information on the energy usage of each machine. This enables you to target and reduce energy consumption, prevent waste and avoid unnecessary costs.

No. With IoT sensors and plug-and-play solutions, TFV can capture data from any mix of machines, new or legacy.

The short answer is yes. There is strong evidence that manufacturers are turning to technology to try and improve efficiency using technology.

We often see manufacturers citing economic pressure as their reason to invest in affordable technology solutions: Facing economic challenges and rising costs, manufacturers are investing in AI, data analytics, and automation (technologies that rely heavily on robust, clean data) and data-driven decision-making to improve productivity and profitability.

Ready to see your factory differently?

FourJaw helps manufacturers of all sizes achieve Total Factory Visibility with affordable, plug-and-play technology that connects to any machine — old or new.

Start your TFV pilot today.