Real-time data enables informed continuous improvement, driving higher manufacturing productivity.

Locate and resolve production matters quicker by removing production bottlenecks easily with real-time data.

JOB TRACKING SOFTWARE FOR MANUFACTURING

Maintaining control and oversight throughout the manufacturing process is essential for achieving efficiency and productivity.

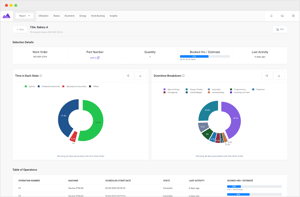

FourJaw’s job-tracking software workspace allows for the centralisation and monitoring of all production operations from start to finish, giving production managers a full view of their factory floor operations.

Stay on Top of Production with Job Tracking

Understand Your Downtime

Tired of not knowing what the main causes of downtime on your jobs are?

Job Tracker reports allow you to evaluate the efficiency of your machines on specific jobs and work orders and identify the most common causes of machine downtime, allowing you to make informed decisions. Learn more about downtime tracking.

Know Your Productivity

Constantly underestimating the time it takes to complete a job?

Our job tracking software features show you how much time was actually spent compared to what was expected, giving you the insights you need to quote more accurately in the future.

Track Progress

Track jobs in real-time with FourJaw manufacturing analytics work booking tool.

- Compare the actual time spent on a works order to the expected time. Use the information to quote more accurately in the future

- Understand which jobs are more profitable to allow you to focus on your production priorities and identify where improvements need to be made

- Improve job scheduling and time management with accurate time expectations and workflow management

- Use historic data to accurately inform decisions and deliver future projects on time

Reporting

FourJaw's machine monitoring captures all the details behind jobs so you can take corrective action where required.

- Run reports on work orders and jobs to evaluate how well your machines were utilised and the most common downtime reasons

- Increase the profitability of jobs. Use data to drive continuous improvement to protect and grow margins by making future work more efficient

- Discover issues in your production line and use actionable insights to improve manufacturing times

What's different about FourJaw?

Frequently Asked Questions

Job tracking software is a digital workspace that allows manufacturers to centralise and monitor production operations from start to finish. This gives managers a full and easy view of all operations from one central location, making production more efficient.

Learn more about downtime monitoring.

FourJaw’s workbooking and job tracking feature is used to monitor and manage the progress of individual jobs in a manufacturing facility. Helping to improve efficiency, reduce downtime, improve lead times, plan resources more effectively and increase transparency in the production process.

Learn more about downtime monitoring.

Job tracking software provides real-time data on job status, enabling manufacturers to quickly identify bottlenecks and make informed decisions to optimise their production process.

The information provided helps automate manual processes and reduces the risk of human error. Typical benefits include:

- Reduced production costs

- Reduced lead times

- More profitable work

- Focus production priorities

- Allocate the right resources more effectively

FourJaw’s manufacturing analytics platform includes real-time machine data to allow you to see key manufacturing productivity metrics such as OEE and utilisation in real-time. FourJaw’s pro subscription is available on a monthly pricing plan and includes the job tracking feature as standard.

With monthly payment plans and self-installation available you can avoid the typically large up-front costs you’d find with other providers. Check out our machine monitoring and job tracking software prices.