Machine Monitoring Software

Real-Time Machine Utilisation, Downtime & OEE,

for any machine in any factory.

FourJaw Manufacturing monitoring software

Here are four reasons why manufacturers choose our simple but powerful manufacturing monitoring software.Operators shouldn’t have to fill out paper forms or key in Excel data.

Automatically capture real-time production data from any machine with our machine monitoring software.

FourJaw captures machine on/off, run time, idle time and programme status automatically.

See your factory’s production data in real time. Monitor live production data from anywhere, at any time.

Manufacturers struggle with manual logs, unreliable downtime forms and incomplete utilisation data.

FourJaw gives you live, objective machine data so you always know what’s running, idle or stopped — across your entire factory

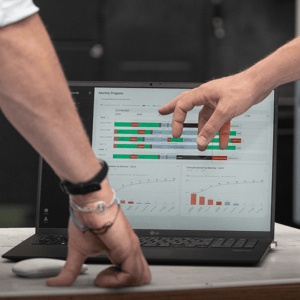

Turn your production data into clear, actionable insights to drive continuous improvement. Make informed decisions to increase productivity, remove bottlenecks and drive sustainable growth.

Real-time downtime alerts enable you to proactively manage production inefficiencies before they escalate. Keeping your operations efficient, machines running and production schedules on track.

Machine Monitoring, Installed in minutes.

Mixed equipment? No problem. FourJaw manufacturing monitoring software works on ANY Machine, regardless of age or type.

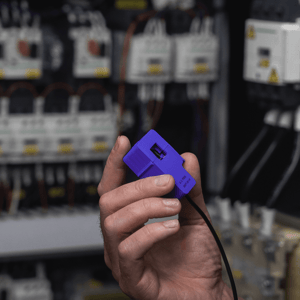

Plug FourJaw’s universal sensor into your machine’s power signal. Zero integration with the PLC or control is required.

Connect the MachineLink IoT device to WiFi and mains power. Your machines begin sending live utilisation and downtime data instantly.

Use data insights to start identifying and removing inefficiencies. Identify waste, target improvements and measure impact with real data.

Machine monitoring. Made Simple.

What if you had complete visibility of your factory, with data at a glance, right as it happens? Now, you can.

FourJaw turns live machine data into clear, usable insights, empowering better decisions across every shift, every site and every machine.

Watch the video or book a demo to see what's possible with our machine monitoring technology.

What Makes FourJaw Different?

Machine monitoring software designed to seamlessly work with any mains-powered manufacturing machine.

FourJaw is trusted by manufacturers in:

Aerospace · Automotive · Food & Drink · Precision Engineering · Medical Devices · Packaging · Machinery · Furniture · Metals · Building Products and many more...

From five machines to 200+, FourJaw delivers value from day one.

*FourJaw works with almost any machine that draws power. Because FourJaw doesn’t rely on PLC integrations, it’s brand-agnostic, making it ideal for manufacturers with machines of varying ages, brands, and types.

Customer Testimonials

"FourJaw has delivered a significant and sustained improvement in the productivity levels we're getting from our manufacturing centres."

Monitoring downtime, eliminating the various causes of waste in our processes, and deploying colleagues to where they are needed most has helped achieve a 30 per cent overall increase in uptime.

“FourJaw is helping us move towards 4.0 based on our S&OP.”

It allows us every month to analyse with the directors to see our strengths and weaknesses and plan forward based on what we find. From a continuous improvement point of view, we now have concrete evidence of where to focus our energy, helping with costings, budgeting and machine utilisation.

“We’ve removed all back orders and are now in a position to deliver orders on time for customers worldwide.”

This is a tangible benefit of our unprecedented increase in machine productivity, and we’ve also improved staff retention with a calmer, less stressful working environment where operators have the autonomy to get on with the job.

Software Features

Manufacturers are tired of manual data collection, Excel spreadsheets and incomplete downtime logs.

FourJaw gives you live, accurate machine data with zero operator burden, so teams can make decisions using facts, not guesswork.

Machine Utilisation

FourJaw provides standardised machine utilisation data, enabling you to identify inefficiencies and optimise existing resources.

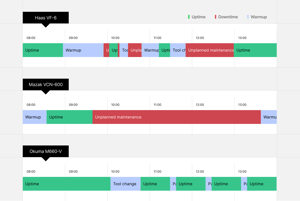

Production Timeline

Identify production bottlenecks in real time with our Timeline View, and drill down to see exactly where production is stalling.

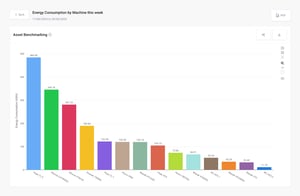

Energy Consumption Reports

Factories often waste energy unnecessarily, while facing increasing pressure to meet sustainability goals. FourJaw's sustainability features help you tackle both challenges at once.

Try an Interactive Guide

Get instant access to FourJaw’s Interactive Intro and see how it transforms manufacturing efficiency

See FourJaw In Action

Share your company details to request a personalised demo and discover the full potential of your factory.

Frequently Asked Questions about machine monitoring software

FourJaw's machine monitoring solution is designed for use on all types of manufacturing equipment.

FourJaw uses Plug-and-play hardware, no PLC integration required, its compatible with Fanuc, Siemens, Heidenhain, Haas, Xyz, Doosan and every major machine type.

Generally, if it has an electrical current, FourJaw can tell you how productive it is (and how much energy it uses).

The system connects machines using non-invasive sensors that link to our MachineLink IoT hardware.

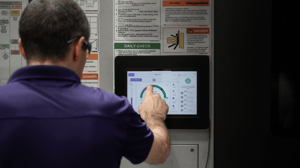

When the MachineLink detects machine downtime, it automatically prompts the operator via the FourJaw tablet to select the reason for the downtime from a predefined list (customisable by you).

The data is then displayed on FourJaw's web-based dashboard, allowing managers to make data-driven decisions in real-time.

Yes, FourJaw's machine monitoring software is designed for use on all types of manufacturing equipment, including.

- CNC machines

- Lathes & milling machines

- Presses & injection moulding machines

- Assembly lines

- Fabrication equipment

- And more...

Generally, if it has an electrical current, FourJaw can tell you how productive it is (and how much energy it uses).

Where conventional systems might read any spindle movement as "productivity", FourJaw accurately detects genuine, money-making productivity. For example, FourJaw can detect when a CNC machine is cutting metal, by observing the rise in current usage during actual work.

This not only provides a more accurate measure of machine efficiency but also ensures consistency in data across all machines, facilitating better decision-making across your factory.

FourJaw captures downtime data through a combination of its MachineLink hardware and tablets mounted on the machines.

When a MachineLink detects downtime, it automatically prompts the operator via the tablet to select the reason for this downtime from a predefined list.

This process is quick and non-disruptive, designed to minimise interruption to the operator's workflow.

By simplifying the input method to just a few taps, FourJaw ensures that accurate downtime reasons are recorded with minimal effort, enabling a comprehensive analysis of machine productivity and downtime causes without impeding your operators.

Yes. Unlike traditional machine monitoring software solutions, we designed our machine monitoring platform to be accessible, not only did we make it easy to install (minimising disruption to your factory floor), but we also made it affordable.

We offer monthly payment plans, and you can install it yourself, so there are no high upfront installation costs often associated with traditional machine monitoring solutions.

Machine utilisation monitoring is the process of tracking how much time a machine is actively running, idle or stopped. It gives manufacturers a real-time view of how effectively their equipment is being used.

FourJaw measure machine utilisation by automatically senses the machine’s electrical activity to determine whether it is running, idle or stopped — with no PLC integration required. This allows you to monitor utilisation across any machine type, new or old.