What is OEE

Understand, manage and optimise processes to improve Overall Equipment Effectiveness.

Everything you need to know about OEE

Overall Equipment Effectiveness, or OEE, is used in manufacturing to measure a machine's productivity.

An OEE report gives factory managers reliable information used to maximise output and improve performance. FourJaw's machine monitoring system tracks machine uptime, which is used to measure OEE Availability.

This page provides further detail about what OEE is, how it's used in manufacturing and how FourJaw's machine/production tracking software enables manufacturers to track and report on Availability and Quality metrics.

What does OEE refer to in manufacturing?

OEE (Overall Equipment Effectiveness) is seen by the majority of manufacturers as the gold standard in productivity monitoring, taking into account Performance, Availability and Quality.

OEE identifies the percentage of manufacturing time that is productive.

An OEE score of 100% means you are manufacturing only good parts (100% Quality), as fast as possible (100% Performance), with no downtime on the machine (100% Availability).

Improve OEE with plug & play machine monitoring software

Improve your factory’s Overall Equipment Effectiveness with our plug & play machine monitoring software, designed to make your factory production lines as efficient, productive and sustainable as possible.

We enable manufacturers to quickly and easily track and measure machine 'Uptime', which is key to measuring the 'Availability' part of OEE.

See Uptime of a single asset, by trend over time, for one or more assets, or view and compare assets side-by-side using our prebuilt Uptime/OEE widgets.

In addition, manufacturers use the Production Quantity Report, which gives you a broader view of Quality data across all your jobs and references, showing total good quantity, scrap quantity, and quality percentage across machines and time periods.

-

Improve production line efficiency

-

Reduce production costs

-

Reduce machine downtime

-

Plan resources more efficiently

-

Track Quality - total good quantity, scrap quantity, and quality percentage

-

Remove inaccurate, manual processes

A guide to improve OEE

Read our latest article to learn about the benefits and drawbacks when using OEE as a measure of manufacturing productivity.Real-time Manufacturing OEE Data

The old saying “You can’t improve what you don’t measure,” holds especially true when it comes to improving your factory’s OEE.

Wherever you are on your OEE journey, deploying a reliable and accurate way to track OEE is fundamental to ensuring you get clean, reliable data from your machines.

FourJaw is an easy-to-install production/machine monitoring platform that enables you to determine your overall equipments Availability and Quality scores which can be used to identify areas where performance can be improved, helping you on your journey to lean manufacturing.

OEE for small-batch and volume production

By using the real-time machine status data, we can calculate OEE Availability figures for the current job, or shift, enabling comparison to previous shifts and encouraging the machine operator and factory floor supervisor to take corrective action if needed.

Factories should aim for an OEE of at least 80%, however, most achieve 60% or less, massively impacting manufacturing productivity and profitability.

Find out more about how our technology can support your OEE performance.

Frequently asked questions

Here's a selection of frequently asked questions relating to OEE along with our answers!

The OEE measure identifies the percentage of manufacturing time that is truly productive, which is where machine monitoring adds massive value.

A manufacturer with an OEE score of 100% means would mean you are manufacturing only Good Parts, as fast as possible, with no Stop Time

The OEE measure in manufacturing looks at three factors; Quality, Performance and Availability. FourJaw's machine monitoring platform is designed to help identify, measure and improve how productive a production line (or machine) is. Therefore if you're looking to start or improve your current OEE measures, then our machine monitoring platform can help you with your manufacturing performance and availability.

Machine monitoring helps drive lean manufacturing otherwise known as lean production as well as the performance and availability parts of the OEE measures.

FourJaw Machine monitoring software at its core, is designed to enable manufacturers to improve (maximise) their manufacturing productivity. Therefore Machine monitoring is a crucial manufacturing technology to ensure manufacturers achieve their lean manufacturing ambitions.

FourJaw machine monitoring was originally designed to monitor the productivity of a machine by identifying downtimes to help drive productivity improvements such as utilisation and OEE.

However, we have recently added Energy Monitoring to our platform features, giving manufacturers Energy usage data combined with Machine productivity data to help reduce their energy usage, energy costs and carbon footprint.

You can find out more about FourJaw's energy monitoring feature here.

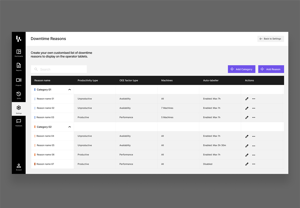

Examples of Availability Downtime reasons include: Machine fault, Tool broken, Set Up, Unplanned maintenance, etc.

Ready to

Learn More?

Looking to measure OEE in your factory? FourJaw can help. Find out more by requesting a free, no-obligation product demo.