OPERATIONAL ALERTS

Identify and resolve potential issues before they can impact your production.

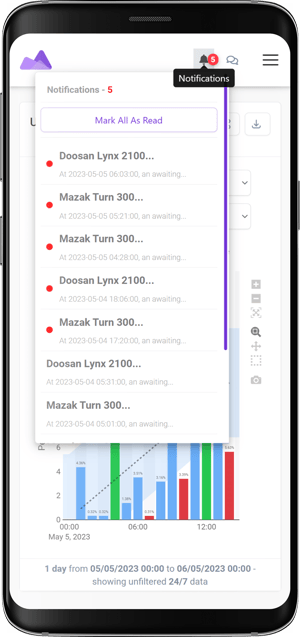

Real-Time Operational Alerts

Are you tired of costly surprises caused by unexpected production issues? Do you wish you could identify and address issues before they escalate?

With our operational alerts feature, you can proactively manage unplanned downtime and keep your manufacturing operations running smoothly thanks to automatic alerts. Notify the right people, for example when a machine is in unplanned downtime or when a job is going to be delayed.

Never Miss An Issue

Operational Alerts is your vigilant watchdog, continuously monitoring your machines for any signs of trouble. When a potential issue is detected, the right person or team is promptly notified, ensuring that corrective action can be taken immediately. Say goodbye to those unwelcome surprises and hello to proactive problem-solving.

- Notify the right people

- Improve communication

- Proactively manage production issues as they arise

- Continuously improve processes

- Reduce the likelihood of future issues

Features

Ensure the right people receive real-time notifications to swiftly address machine-related challenges.

Select the machines to apply the alert to, and choose the individuals or teams who need to be notified.

From machine faults and unplanned maintenance to unlogged downtime reasons.

Receive alerts via email and in-app notifications, ensuring the right people are informed promptly.

.jpg?width=300&name=Background%20Banner%20(1).jpg)

Define specific downtime periods that trigger alerts, allowing for proactive maintenance actions.

Stay informed when machines go offline, enabling quick response and reduced downtime.

Monitor machine status and receive alerts in real-time, allowing for immediate action.

FourJaw Pricing

Plug-and-Play Installation that works on any machine. Training & ongoing support are all included in the price.